Tips to Prevent Encapsulation Resin Yellowing, Keeping Your Products Looking Fresh for Longer!

With the continuous advancement of industrialization, electronic devices are increasingly developing towards miniaturization, integration, and precision. Potting compounds, as a type of adhesive with flow properties, play a crucial role in effectively filling the gaps of precision components, tightly wrapping the components, and forming a strong protective barrier. Customers who frequently use potting compounds often encounter various issues during use. Shanghai Hinnel New Material Technology Co., Ltd. introduces how to avoid yellowing of potting compounds and what to do if yellowing occurs. Let's take a look!

Shanghai Hinnel

2025/02/18

Why potting adhesive may yellow:

When potting adhesive is used outdoors, fillers may react with certain chemicals, leading to discoloration. Generally, over time, adhesives may yellow. Once yellowed, it only affects the color of the adhesive layer and has little impact on performance. In fact, transparent potting adhesive may show slight yellowing after a long curing time, which is mostly normal. As long as the various properties of the transparent potting adhesive remain unchanged after yellowing, it can still be used.

How to avoid yellowing:

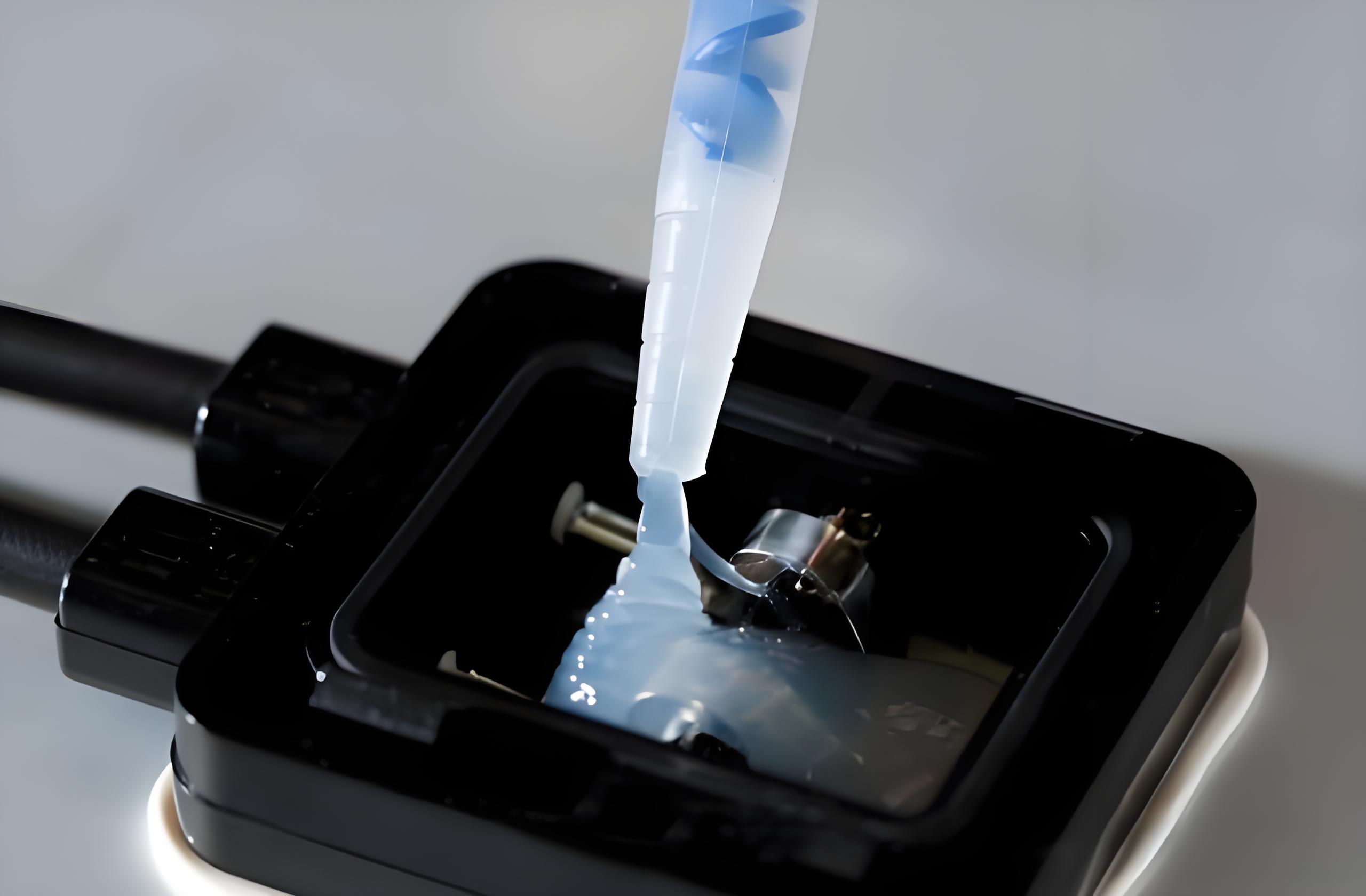

11. Correct operation: During the mixing process,ABthe content of the agent is very important. It should not be measured by volume ratio but by weight ratio. After accurate weighing, mix the two sets of materials evenly to resist yellowing as much as possible.

22. Choose quality products: Not all products will yellow. During the purchasing process, understand the quality and performance of transparent potting adhesive. Collaborate with reputable suppliers for more assurance, such as Hinnel New Materials, which offers potting adhesives that are widely applicable in industries such as new energy, military, medical, aviation, shipping, electronics, automotive, instruments, power supplies, and high-speed rail.

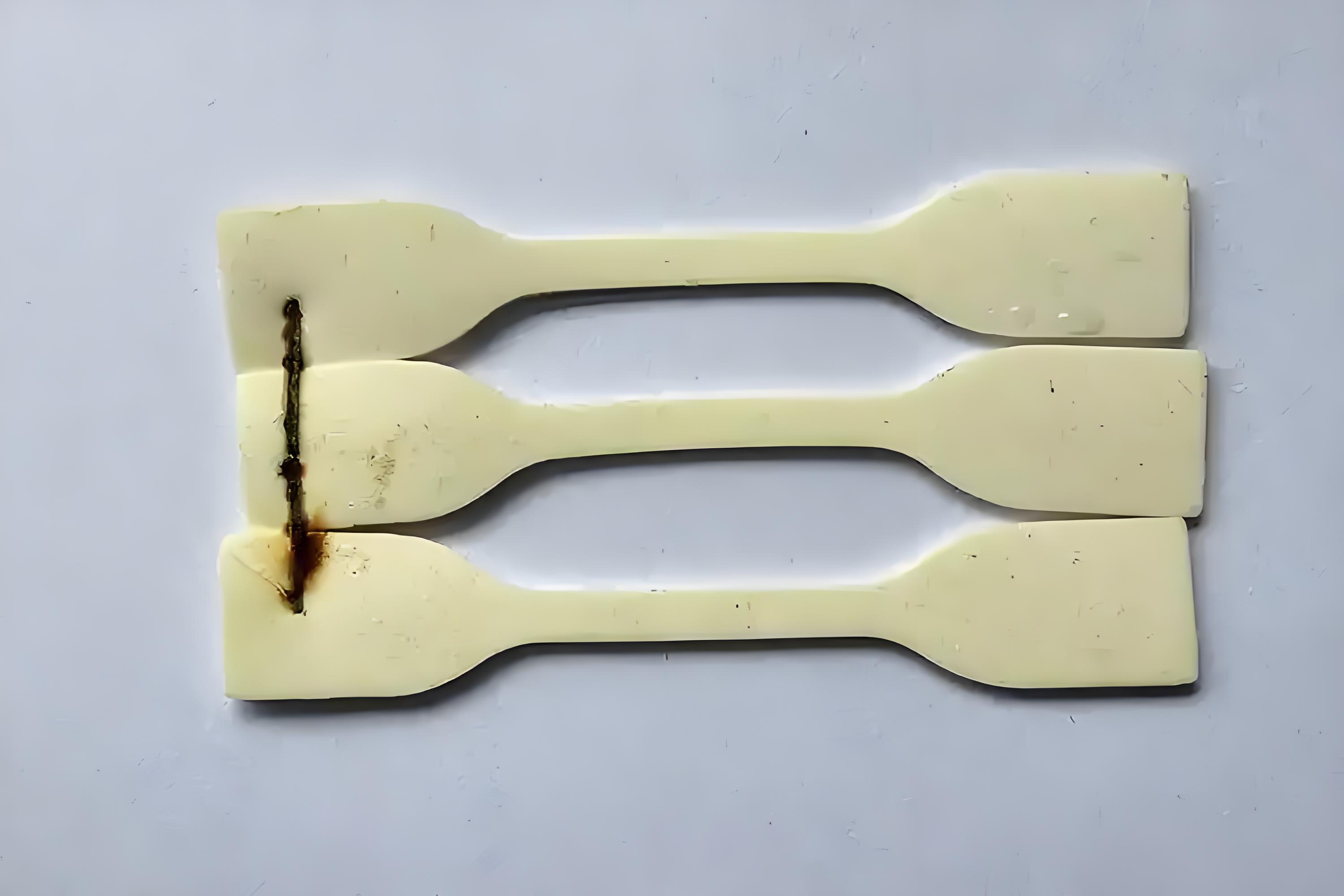

3. 3. Strict testing: Conduct strict testing during the production process to ensure the quality of the potting adhesive meets requirements.

4. Storage precautions: During the storage of potting adhesive, avoid direct sunlight and high-temperature environments, and maintain a dry and ventilated condition to prevent oxidation.

Methods to remove yellow potting adhesive:

1. Soaking method

Soak the power module in a solvent, allowing the solvent to penetrate the yellow potting adhesive, softening and thinning it. Common solvents include acids, bases, ketones, and alcohols. Gasoline or alcohol is commonly used; the specific solvent can be chosen based on actual conditions. The soaking time is generally more than24hours, but the specific time should also be adjusted based on factors such as the thickness and curing time of the yellow potting adhesive. After soaking, use a small knife or aluminum sheet to scrape off the yellow potting adhesive.

2. Scraping method

Use a flat tool such as a scraper or fine sandpaper to scrape off the yellow potting adhesive. Since potting adhesive has a high viscosity, considerable force is needed to scrape it off. Be careful not to use overly strong tools or scrape too much to avoid damaging the power module or affecting its lifespan.

The above is an introduction to the yellowing problem of potting adhesive that is often encountered during use and its solutions. For more knowledge about potting adhesive, please consult us!

Note: Some content is sourced from the internet; contact us for removal if there is any infringement.

> Recommend reading

Shanghai Hinnel

2025/04/24

Product applications and performance characteristics of polyurethane structural adhesive

Shanghai Hinnel

2025/04/17

What are the common problems and solutions for silicone thermal potting glue?

Shanghai Hinnel

2025/04/15