Electronics and Electrical Appliances

In electronic devices, the fixation of components is a very important aspect. An excellent fixation scheme can ensure the stability of the component's position, preventing loosening or displacement caused by factors such as vibration and temperature changes. At the same time, good fixation can also ensure the stability of electrical performance, reducing signal loss or power failure caused by poor contact. Managing heat and temperature in these systems is crucial for extending lifespan, especially for components. Hinnel is confident in providing any solutions for adhesives used in electronic appliances.

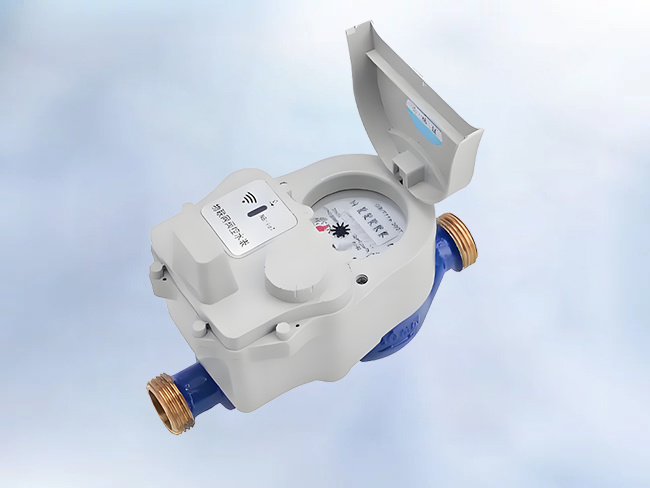

[Smart Water Meter Encapsulation]

| Adhesive Application Area: Water Meter Head Recommended Adhesive: Epoxy Resin Encapsulation Adhesive • Temperature range covers -50 to 230℃ |

[Control Cabinet Door Bonding]

|

Adhesive Application Area: Control Cabinet Door Frame Recommended Adhesive: Silicone Adhesive Sealant • Hinnel offers three major product categories: South University Dehydration Type, Dehydration Titanium Type, and Dehydroxylamine Type

|

[Reversing Radar Encapsulation]

| Adhesive Application Area: Adhesive for Reversing Radar Recommended Adhesive: Polyurethane Encapsulation Adhesive • Good fluidity • Good infiltration performance • Excellent heat resistance and thermal conductivity • Flame retardant performance meets UL94V-0 requirements |

[Projector Adhesive]

| Adhesive Application Area: Battery Module Packaging Recommended Adhesive: Epoxy Resin Encapsulation Adhesive • Temperature range covers -50 to 230℃ |

In summary, using adhesives is an effective way to solve moisture-proof and corrosion-proof sealing problems in electronic appliances. By applying sealant to key areas of electronic appliances, a strong sealing layer can be formed, keeping the interior dry for a long time and extending the lifespan of the equipment. In addition, this solution also has high safety, ease of operation, and strong applicability, making it widely applicable in moisture-proof sealing projects for various electrical equipment.

∗Some images in this article are sourced from the internet. If there is any infringement, they will be removed immediately.