IGBT/SiC MOSFET Packaging Adhesive Solutions

Abstract: Power module packaging is a highly integrated discipline, involving fields from material research to process application, from inorganic materials to polymer materials, and from large intelligent production equipment to computer simulation analysis. The forms of power module packaging are also diverse, with new packaging forms emerging continuously, posing greater challenges to packaging materials. Shanghai Hinnel New Materials provides silicone and epoxy resin packaging adhesive solutions.

1. What is IGBT

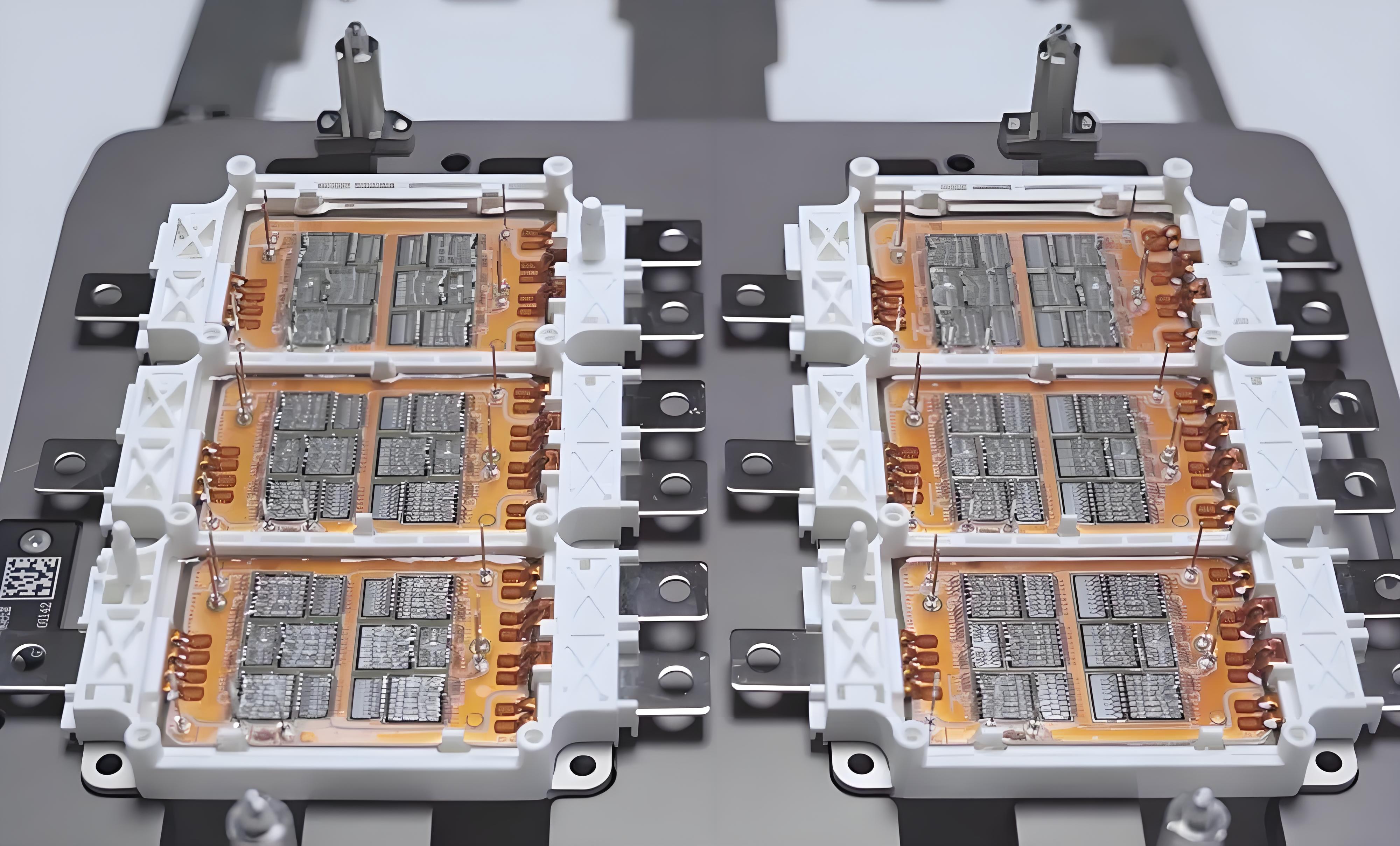

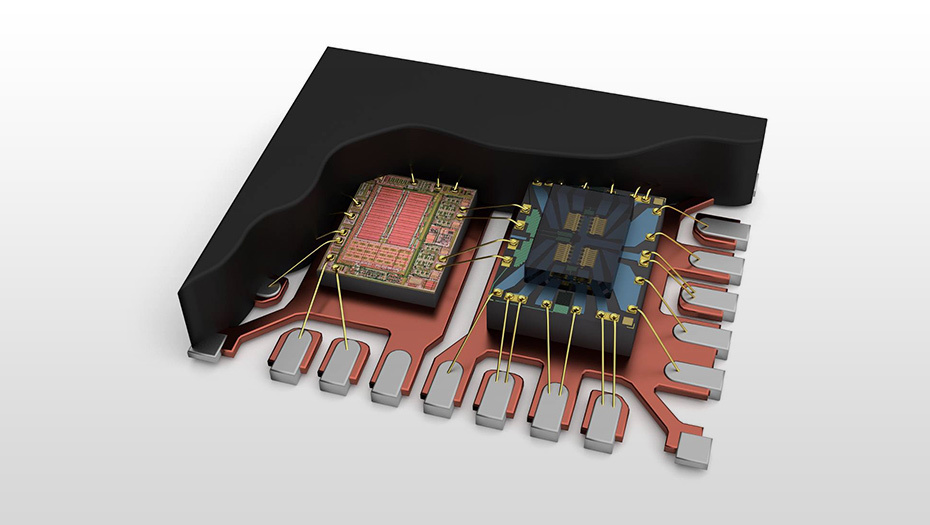

IGBT, or Insulated Gate Bipolar Transistor, is a typical power module characterized by fast control speed, low drive power, and reduced saturation voltage. It is widely used in advanced rail transit, power transmission and distribution, electric vehicles, new energy, and smart home appliances, among other electrified fields, and is known as the 'CPU' of electric power (power) processing. The packaging forms of IGBT modules are classified into crimped and welded types based on the assembly process and installation methods of the chip or die. Various polymer materials are also used in the packaging process, such as silicone sealant, silicone gel, epoxy potting compound, thermal conductive silicone grease, nylon, and epoxy molding compounds, which mainly serve the purposes of insulation protection, moisture sealing, and mechanical support, playing an important role in improving the voltage resistance of IGBT and reducing partial discharge.

2. Packaging Forms of IGBT

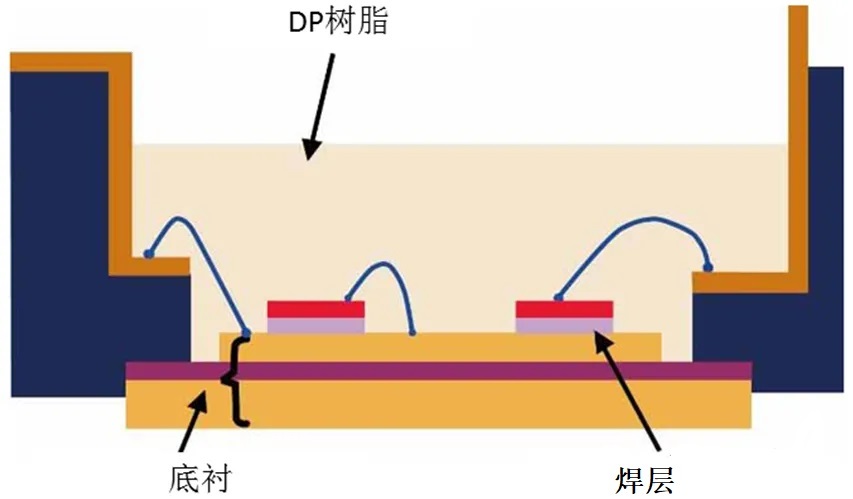

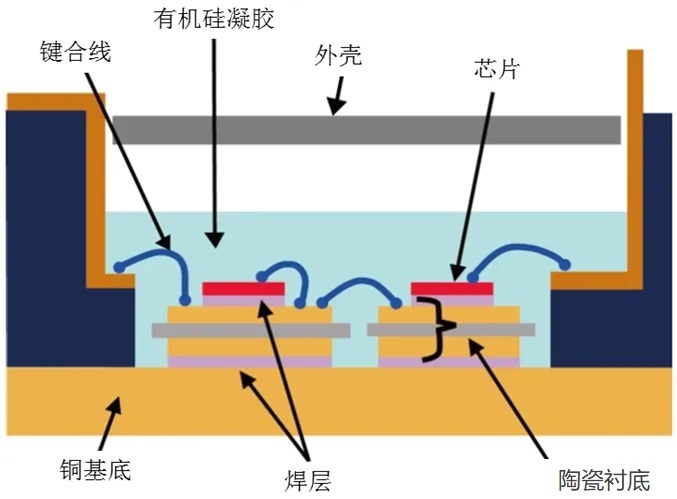

The different packaging forms of IGBT modules lead to the use of different polymer materials. For welded IGBT modules, a typical packaging method combines silicone gel, epoxy potting compound, and plastic housing. This packaging method not only ensures the electrical insulation performance of the module but also provides good mechanical strength protection, mainly applied in the packaging of IGBT modules for rail transit.

There are also methods that directly combine silicone gel with plastic housing for packaging, mainly applied in IGBT modules for electric vehicles and wind power.

|  |

3. Application of Silicone in IGBT Packaging

Silicone, as a stable and reliable polymer material, has the following main applications in IGBT: 1. Silicone adhesive sealant (before potting with silicone gel, silicone adhesive sealant is needed to fix and seal between the housing and the base to prevent silicone gel from overflowing during potting) 2. Potting silicone gel. 3. Thermal conductive silicone grease (i.e.the high thermal conductive silicone grease applied between the module and the heat sink).

Performance Requirements of Silicone in IGBT Packaging:

1. Silicone Adhesive Sealant:

In housing sealing solutions, there are two types of sealants available: addition-type and condensation-type. Addition-type silicone adhesive sealant requires high-temperature curing, with the advantage of not causing silicone gel poisoning after curing and curing faster than condensation-type silicone sealant. Condensation-type silicone adhesive sealant cures by absorbing moisture from the air, and the complete curing speed is relatively slow, generally requiring 24-72 hours, and needs special formulation design to prevent silicone gel poisoning.

2. Silicone Gel:

Silicone gel is a special silicone rubber that exists in both liquid and solid states, characterized by 'solid-liquid coexistence'. It is very soft and does not exert mechanical stress on the IGBT chip, maintaining its softness even at temperatures ranging from -50°C to 200°C, effectively protecting the IGBT chip from moisture erosion, achieving insulation, moisture-proofing, dust-proofing, shock absorption, and corrosion resistance. When selecting silicone gel for specific IGBT applications, the following key characteristics need to be considered:

① High-Temperature Resistance: Silicone gel needs to maintain stable performance within the operating temperature range of the IGBT module, which is typically -40°C to 150°C, but some applications may require higher temperature tolerance, such as IGBT modules in new energy vehicles that may face higher temperature challenges.

② Electrical Insulation Performance: Silicone gel should have high dielectric strength and volume resistivity to ensure reliable insulation protection under high voltage.

③ Temperature Cycling Resistance: IGBT modules will experience temperature cycling in practical applications, so silicone gel needs to have good temperature cycling resistance to maintain long-term reliability.

④ Low Stress and Flexibility: Silicone gel should have low internal stress and good flexibility to reduce mechanical stress on the IGBT chip and improve packaging reliability.

⑤ Moisture and Water Resistance: Silicone gel needs to effectively prevent moisture and water from eroding the IGBT module, protecting the device from the effects of humid environments.

⑥ Shock Resistance: Silicone gel should have good shock resistance to protect the IGBT module from damage during mechanical impacts.

⑦ Chemical Stability: Silicone gel needs to have good chemical stability, not easily reacting adversely with other materials, ensuring long-term stability.

⑧ Thermal Aging Characteristics: Silicone gel needs to have good thermal aging characteristics during long-term use, especially in high-temperature environments, to maintain its performance without degradation.

⑨ Environmental Adaptability: Silicone gel needs to adapt to various environmental conditions, including ozone resistance, radiation resistance, and weather aging resistance.

⑩ Material Compatibility: Silicone gel needs to have good compatibility with other materials in the IGBT module (such as substrates, heat sinks, etc.) to ensure the overall reliability of the packaging.

Depending on different application requirements, other characteristics of silicone gel, such as transparency, yellowing resistance, and curing speed, may also need to be considered. By comprehensively considering these factors, suitable silicone gel packaging materials for specific IGBT applications can be selected.

|  |

Ordinary linear polydimethylsiloxane (PDMS) gel becomes brittle after being stored at high temperatures above 175°C for more than 1000 hours, with significant declines in mechanical and dielectric properties, and may even crack. As the packaging forms of IGBT modules continue to evolve, higher demands are placed on the organic silicone gels used for packaging. The high purity, high-temperature resistance, and high dielectric properties of organic silicone gels for IGBT module packaging are key development directions that need to be focused on. The insufficient purity of organic silicone gels is due to the purity of raw materials and the preparation process. Organic silicone gels with excessively high ionic content can undergo yellowing, hardening, and metal ion migration in long-term high-temperature and high electric field environments, directly affecting the reliability of IGBTs. Therefore, the issue of organic silicone gel purity needs to be given special attention.

4. Application of Epoxy Resin in IGBT Packaging

Epoxy resin is a high molecular material that contains more than two epoxy groups in its molecular chain segments. It has strong processability, good dielectric properties, and high mechanical strength, making it widely used in various fields. Epoxy resin materials are mainly used in IGBT module packaging for potting.

The epoxy potting adhesive used for IGBT module potting is generally applied after the silicone gel potting is completed. After curing, it forms a dense and hard protective layer on top of the silicone gel, which can protect and enhance the integrity of the module, providing practical significance for improving the module's resistance to mechanical shock. This packaging structure is more commonly used in IGBT modules for rail transportation.

Performance requirements for epoxy resin adhesives in IGBT packaging:

The epoxy adhesive used for IGBT module potting mainly adopts a two-component form, made from special epoxy resin, inorganic fillers, and additives. Its cured product has high flame retardancy and a low CTE value, effectively isolating the impact of adverse external environments.

Epoxy potting adhesives made from ordinary bisphenol A epoxy resin can shrink and crack at low temperatures of -40°C, leading to packaging failure. At high temperatures exceeding 150°C, they can soften, losing some mechanical and dielectric properties. After a period at temperatures above 200°C, there is a possibility of chemical bond breakage, resulting in the generation of small molecular volatile substances. Therefore, there are many issues with the packaging of silicon carbide IGBT modules operating at temperatures reaching 200°C. The high-temperature resistance, crack resistance, low CTE value, and improvements in the application process of epoxy adhesives for IGBT module potting are key development directions that need to be focused on.

Shanghai Hinnel New Materials Technology Co., Ltd. has developed an epoxy adhesive suitable for IGBT potting using bisphenol A epoxy and anhydride. Its performance can withstand over 1000 cycles of cold and hot shock tests from -40°C to 125°C. Based on this, a model equation for the viscosity of the epoxy adhesive was established, predicting the flow characteristics of the epoxy adhesive within 50-90°C, providing valuable references for the application process. To develop a better heat-resistant IGBT epoxy potting adhesive, the technical team researched and used high-temperature resistant special epoxy resin as the main resin, combined with high-temperature resistant silicon carbide and flame-retardant aluminum hydroxide as fillers, to prepare an IGBT epoxy potting adhesive with good mechanical properties and high dielectric properties at high temperatures. Its glass transition temperature exceeds 200°C, meeting the potting requirements of high-power IGBT modules.

|

5. Recommended Adhesives for IGBT Module Packaging

| Product Category | Product Type | Product Model | Adhesive Application Points | Curing Method | Main Performance |

| Organic Silicone Sealant | Dehydration Type | HN733T | Shell Frame Sealing | Room Temperature Curing | Room Temperature Curing, Low Viscosity Transparent |

| Organic Silicone Sealant | Dehydration Type | HN736W | Shell Frame Sealing | Room Temperature Curing | Titanate System, Not Easily Causes Silicone Gel Poisoning |

| Organic Silicone Sealant | Addition Type | HN818 Series | Shell Frame Sealing | Heating Curing | High Temperature Fast Curing, Will Not Cause Silicone Gel Poisoning |

| Organic Silicone Gel | Addition Type | HN5272 Series | Potting Protection | Heating Curing | Low Hardness, Very Soft, High Purity, Resistant to Yellowing |

| Epoxy Resin Adhesive | Anhydride Type | HN6300 Series | Potting Protection | Heating Curing | Low Viscosity, High TG, High Temperature Resistance, Crack Resistance |

Conclusion: In the packaging process of high-performance power semiconductor devices such as IGBT (Insulated Gate Bipolar Transistor) and SiC MOSFET (Silicon Carbide Metal Oxide Semiconductor Field Effect Transistor), choosing the right packaging adhesive is crucial. These advanced materials must not only possess good electrical insulation, high thermal stability, and chemical corrosion resistance but also meet the increasing demands for power density and long-term reliability. The organic silicone and epoxy resin packaging adhesive solutions provided by Shanghai Hinnel New Materials are developed based on a profound understanding of these needs. Organic silicone packaging adhesives, with their excellent high-temperature and aging resistance, as well as good flexibility and adhesion, are ideal choices for protecting power modules from environmental erosion and enhancing overall lifespan. Epoxy resin, due to its cost-effectiveness, good processability, and high mechanical strength, occupies a place in cost-effective packaging applications. Both ensure excellent sealing effects and thermal management performance during the packaging process through precise formulation and advanced processes, providing solid guarantees for the efficient and stable operation of power devices such as IGBT/SiC MOSFET.

∗Some images in this article are sourced from the internet. If there is any infringement, they will be removed immediately.