Automobile Traffic

Adhesives are essential raw materials in automobile production. In automobile manufacturing, the use of good bonding technology can improve driving comfort, reduce noise, dampen vibrations, lighten weight, lower energy consumption, simplify processes, and enhance product quality. Therefore, adhesives play an irreplaceable role in vehicle design and manufacturing.

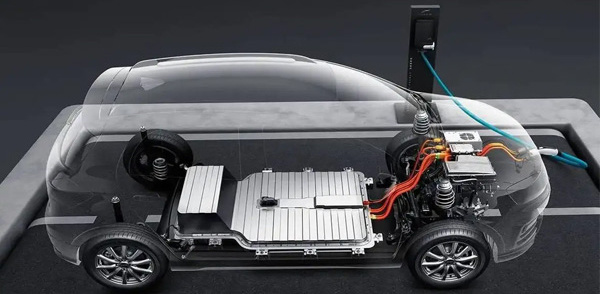

Battery potting adhesive

Function: Filling the gaps within the battery module, providing thermal conductivity, flame retardancy, moisture resistance, and shock resistance.

Epoxy potting adhesive: High thermal conductivity, with good insulation, compressive strength, and high bonding strength.

Silicone adhesive: Excellent insulation, good adhesion, moisture resistance, shock resistance, corona resistance, and leakage resistance.

Motor electronic control housing bonding and sealing

Function: Suitable for CIPG sealing process, quick curing with heating, easy to use, can replace imported similar products, used for bonding the motor electronic control frame of new energy vehicles, sealing and protecting ECU sensors, ABS, and battery pack housings, as well as sealing and protecting circuit boards and modules.

Silicone bonding and sealing adhesive: Fast curing speed; excellent electrical insulation; non-corrosive to substrates; simple and convenient to use; available in various colors; products with various viscosities; the silicone elastomer formed after curing has very good adhesion to most substrates.

Charging pile thermal conductive potting

Function: After curing, the potting product has excellent adhesion to the substrate, achieving moisture-proof, waterproof, dust-proof, shock-proof, and insulation. It can be used for thermal conductive potting of various complex components such as charging piles.

Silicone thermal conductive potting adhesive: No solvents or by-products, very low shrinkage; good adhesion, flame retardancy, and high thermal conductivity; good flow performance and resistance to thermal shock.

Automotive lamp sealing and bonding

Function: With bonding and sealing properties, heat resistance, cold resistance, weather resistance, thermal conductivity, electrical characteristics, and many other excellent properties to protect components from moisture, dust, dirt, and humidity.

Silicone bonding and sealing adhesive: Low volatility, low odor, compliant with RoHS and REACH environmental certifications; excellent high and low temperature resistance, with a temperature range covering -60 to 315°C; available in various packaging specifications to adapt to various dispensing equipment.

Note: Some images in this article are sourced from the internet. If there is any infringement, they will be deleted immediately.