Medical silicone gel

Designed for applications requiring high purity,

with biocompatible medical applications.

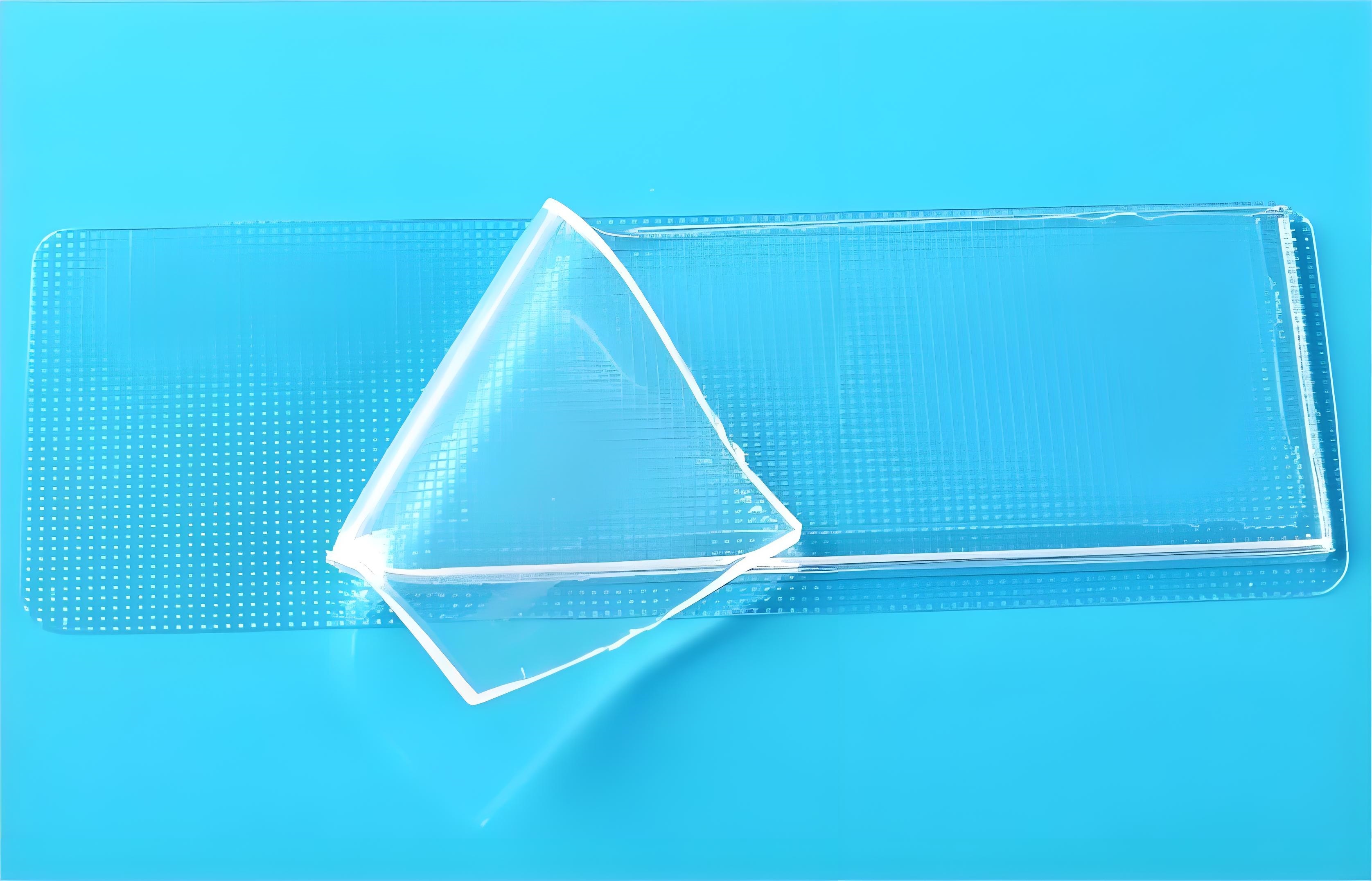

Shanghai Hinnel medical silicone gel is a silicone elastomer used in wound dressings, with different initial tack and peel strength.

It has good biosafety, is gentle and low-sensitizing, and does not cause secondary damage to the skin or wounds.

Suitable for a series of products such as silicone gel scar patches, foam dressings, tapes, adhesive bandages, and silicone gel patches.

Hinnel@Gel 5200 is a two-component platinum-catalyzed silicone gel, suitable for scar patches.

• Multifunctional, curing cycle and temperature are controllable.

• Low viscosity.

• Non-sensitizing, non-irritating.

• No cytotoxicity.

• Gentle adhesion to the skin, low peel strength.

Hinnel@Gel 5250 is a two-component platinum-catalyzed silicone gel, suitable for wound care, silicone gel foam dressings, chronic wound dressings, adhesive bandages, negative pressure wound dressings, scar and wrinkle care, fixation of medical devices and wearable devices, sensor fixation patches, and other types of fixation patches.

• Complies with biocompatibility standards.

• Can be removed non-invasively, reducing the pain of dressing changes, with no secondary damage.

• Good chemical stability.

Hinnel Product Features

Environmentally friendly, solvent-free, and no curing by-products

Can cure at room temperature or be quickly cured with heat

Has permanent pressure-sensitive adhesion to most materials

Excellent self-repairing function

Hardness can be adjusted by oneself

Excellent stability

Good biocompatibility and breathability

| Product Model | Quality Ratio | Mixing Viscosity | Operation Time | Curing Time | Peeling Force | Color | Main Characteristics |

| A:B | cps/25℃ | min/25℃ | min /℃ | N/2.5cm | - | ||

| HNGel5200 | 1:1 | 800±100 | 180 | 25℃×6h or 80℃×60min | 0.1 | Transparent | Low viscosity, non-sensitizing, non-irritating, non-cytotoxic, gentle adhesion to skin, low peeling force. |

| HNGel5250 | 1:1 | 11000±2000 | 90 | 25℃×2h or 120℃×10min | 0.6 | Transparent | Meets biocompatibility standards, can be removed non-invasively, reduces dressing change pain, no secondary injury. |

Discover the advanced healing power of our Medical Silicone Gel. This clinically proven formula is specifically designed to manage and improve the appearance of scars, resulting from surgery, burns, or injuries. It creates an optimal moist environment to support the skin's natural regeneration process, helping to flatten, soften, and smooth discolored scars over time. Trust in a solution that is both effective and gentle for your skin recovery journey.

Our premium Medical Silicone Gel is engineered with a self-drying technology that forms a protective, breathable sheet over the skin. This transparent layer works continuously to hydrate the scar tissue and regulate collagen production, which is crucial for reducing scar texture and redness. The non-greasy formula absorbs quickly without sticking to clothing or bedding, making it ideal for use on various parts of the body for consistent and comfortable application.

Safety and simplicity are at the core of our product. This gentle Medical Silicone Gel is non-irritating and suitable for all skin types, including sensitive skin. It is free from steroids, fragrances, and parabens, ensuring a minimal risk of adverse reactions. Easy to apply with a fingertip or gentle massage, it integrates seamlessly into your daily skincare routine, empowering you to take an active role in your scar management with confidence and ease.

Begin your path to renewed skin with this exceptional Medical Silicone Gel. Consistent daily use is key to achieving visibly improved scar appearance, making it an essential part of post-operative care and wound healing. Embrace the proven efficacy of a top-tier Medical Silicone Gel to help restore your skin's smoothness and tone, supporting your overall confidence and well-being.

Our products are more than that · · · ·

Contact us: get more product information/apply for samples now/work with you to develop solutions tailored to your requirements and processes.

Usage Process

1. Base material (PU/TPU/PE film needs to be sampled and tested before coating to see if it will make the platinum catalyst in the silicone gel ineffective), coated with primer, the recommended coating weight is 7-10g/m2.

2. Weigh components A and B at a ratio of 1:1, mix thoroughly and defoam (can be mixed with a mixer or a static mixer, when mixing with a static mixer it is recommended to use a MIXPAC™ static mixer with more than 24 sections).

3. Use the coating machine to coat the silicone gel, the recommended coating weight is 100-200g/m2, the specific coating weight according to the actual needs.

4. At room temperature of 23-25℃, it is recommended to use the product within 15 minutes (10 minutes in summer and 20 minutes in winter) for hand mixing and 30 minutes for static mixer mixing.

5. The baking temperature is recommended to be between 110-120℃, the baking time is recommended to be between 4-5 minutes, the baking time can be shortened accordingly with the increase of the baking temperature, the specific parameter settings need to be confirmed according to the actual situation on site.

Shanghai Hinnel provides innovative adhesive solutions for bonding, sealing, potting, thermal conductivity, and protection. Our staff works with customers to help them add value to their products. In an ever-changing marketplace, we continue to innovate, respond quickly, and are committed to providing professional products and technical support to our customers worldwide.