Silicone gel

Designed for precision components to have good low-stress protection in mechanical vibration and harsh environments such as cold and heat cycles.

It has excellent fluidity, very good self-defoaming performance, and process operability. It can be used for a long time in the temperature range of -65 to 200°C, and it has excellent electrical performance and chemical stability, with physiological inertness.

Hinnel silicone gel maintains permanent pressure-sensitive adhesion to most materials without the need for a primer after curing, has excellent self-repairing capabilities, and can provide better sealing performance in case of minor damage.

Hinnel silicone gel has characteristics such as low oil permeability, low volatility, and anti-poisoning. We offer a variety of product combinations from viscous jelly-like to elastomer, suitable for applications in different industries.

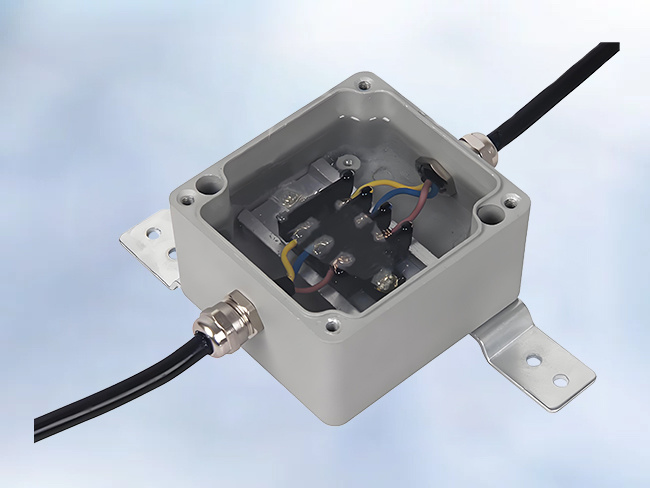

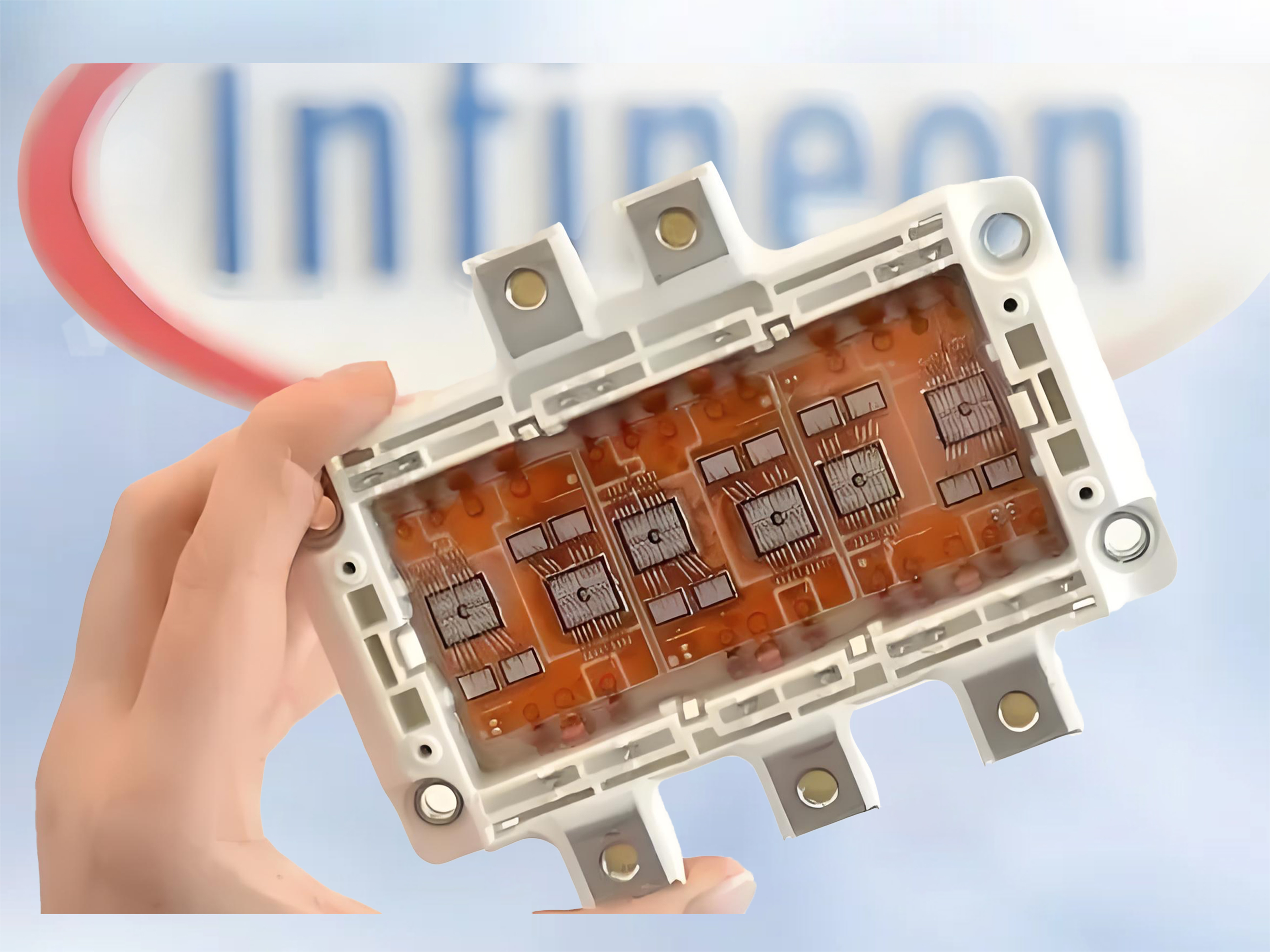

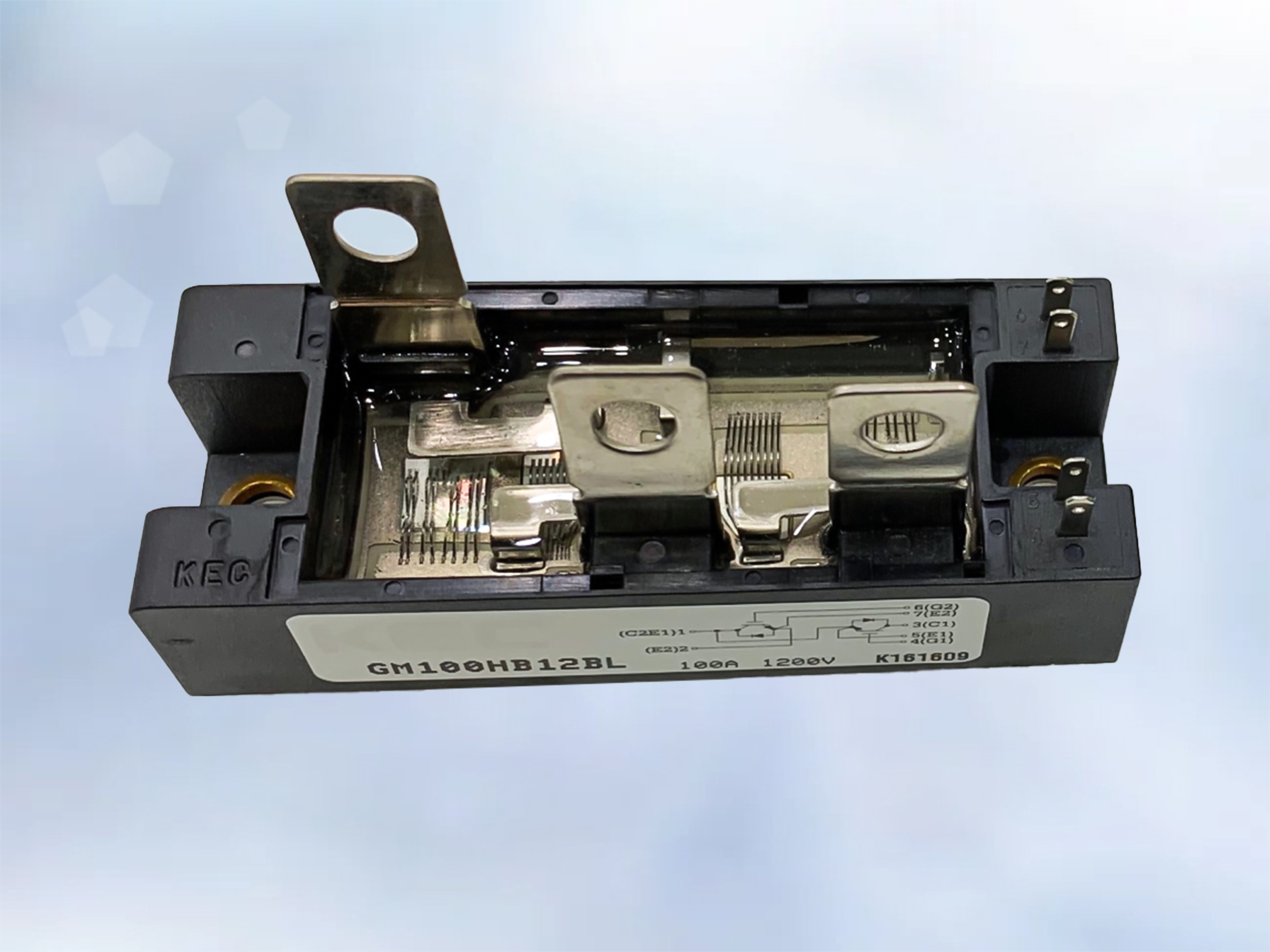

Product use: for low-stress protection in precision devices; insulation protection for power devices such as IGBT; waterproof sealing for instruments, junction boxes; waterproof sealing for automotive electronics and sensors; transparent potting for solar and optoelectronic devices.

Product Usage: Used for low stress protection in precision components; Insulation protection for power devices such as IGBT; Waterproof sealing of instruments and junction boxes; Waterproof sealing of automotive electronics and sensors; Transparent encapsulation of solar and photovoltaic equipment

Hinnel Product Features

Excellent fluidity

Very good self-dispersion performance

Very low oil seepage rate

High transparency, resistant to yellowing

Environmentally friendly, solvent-free, no curing by-products

Can cure at room temperature or be quickly cured with heat

Permanent pressure-sensitive adhesion to most materials

Excellent self-repairing function

Products with various hardness and curing times are available

Adjustable hardness

Excellent stability

| Model | Quality Ratio | Mixing Viscosity | Operation Time | Curing Time | Penetration | Color | Main Characteristics |

| A:B | cps/25℃ | min/25℃ | min /℃ | 1/10mm | - | ||

| HNGel5270 | 1:1 | 1000±100 | 20~40 | 25℃×4h or 80℃×30min | 200±20 | Transparent | Colloidal soft, high strength and elongation, excellent waterproof sealing performance, colloid is not easily broken despite frequent damage, and the colloid can be bonded on both sides and separated. |

| HNGel5271 | 1:1 | 400±100 | 20~30 | 25℃×2h or 60℃×15min | 200±20 | Transparent | Very good adhesion, excellent anti-poisoning, excellent waterproof and insulation performance, suitable for potting of circuit boards, controllers, etc. |

| HNGel5271K | 1:1 | 400±100 | 3~5 | 25℃×15min or 80℃×5min | 200±20 | Transparent | Very good adhesion and very fast curing speed, anti-poisoning, waterproof, and good insulation performance. |

| HNGel5272 | 1:1 | 1000±100 | 60~90 | 25℃×4h or 80℃×30min | 300±20 | Transparent | Very soft, excellent self-repairing ability, resistant to yellowing, low stress, low oil permeability, suitable for potting of power modules such as IGBT. |

| HNGel5272J | 1:1 | 1000±100 | 40~60 | 25℃×4h or 80℃×30min | 5A | Transparent | Solid gel, high colloidal strength, optical transparency, UV resistant, yellowing resistant, used for potting protection of automotive electronic components. |

| HNGel5272D | 1:1 | 1000±100 | 20~40 | 25℃×4h or 80℃×30min | 20~30A | Transparent | High colloidal hardness and strength, non-sticky surface, good waterproof performance, high light transmittance, suitable for potting of products without external cover protection. |

| HNGel5277 | 1:1 | 1000±100 | 20~40 | 25℃×4h or 80℃×30min | 80±10 | Transparent | Transparent solid gel, optical transparency, resistant to yellowing, non-sticky, with slight adhesion to the shell, good waterproof performance. |

Our products are more than that · · · ·

Contact us: get more product information/apply for samples now/work with you to develop solutions tailored to your requirements and processes.

Usage

Mixing - Use manual or automatic equipment to evenly mix the A/B components in proportion (weight ratio), and be sure to stir evenly. In situations where gas mixing is sensitive, the stirred adhesive solution needs to be vacuumed at a vacuum degree of -0.09MPa or above for 3-5 minutes. When there is a large amount of colloid, the degassing time should be appropriately extended. Large scale production can use automatic measuring/mixing/gluing equipment.

Pouring - Can be done manually or with automatic sealing equipment equipped with vacuum pumping devices and material cylinder insulation devices. Place the pouring port of the component to be sealed horizontally upwards, pour in the sealing glue within the operable time, and self level.

Curing - Cure according to the curing temperature specified in the product technical parameters. The curing time of the additive product largely depends on the temperature, size, and thermal conductivity of the product used for sealing. In short, the higher the temperature at which colloids are heated, the faster they solidify.

In terms of the relationship between curing temperature and time, time refers to the curing time after the material reaches the target temperature. Consideration should be given to the heating process of the oven itself, components with strong heat storage capacity, or other situations that may delay the material from reaching the target temperature.

Precautions

The A/B components should be weighed strictly in proportion, and after mixing, they must be stirred evenly to avoid affecting the curing effect.

HNGel 5271 is difficult to harden when in contact with materials containing sulfur, ammonia, unsaturated hydrocarbon plasticizers, organic metal compounds - especially organotin compounds. Common substances include rosin, natural rubber, etc. If you don't know if a substance will hinder curing, you should first conduct a test to verify their compatibility.

The recommended mixing ratio for HNGel 5271 is A: B=1: 1. After curing, it is soft and sticky. Increasing the amount of component B will form a harder and non sticky gel, and increasing the amount of component A will form a softer and more viscous gel. Because of packaging reasons, we only accept A: B=1: Order 1. Customers can change the ratio according to their needs to achieve the desired hardness and viscosity.

Storage and Shelf Life

HNGel 5271 can be stored for at least 12 months in a sealed factory packaging at 5-30 ℃. The shelf life is marked on the label of each product's outer packaging. Products that have exceeded their shelf life must be tested for normal performance before they can be put into use.

Warning Message

Before using this product or any product from Shanghai Hinnel, please refer to the Material Safety Data Sheet (MSDS) and the instructions on safe use and handling on the product label. If you have any questions, please feel free to contact us at any time.

Common Problem:

Poisoning is a common problem in the use of addition silicone thermal conductive potting adhesive. Poisoning refers to the phenomenon that the silicon gel is exposed to compounds containing N, P, S, Sn, Pb, Hg, As, etc. during the curing process, which affects the activity of the PT platinum catalyst, causing the contact part not to solidify.

Common substances that can cause poisoning include natural rubber, sulfur-containing, ammonia, unsaturated hydrocarbon plasticizers, organometallic compounds (especially organotin compounds), soldering flux, rosin, incompletely cured condensed silicone sealant, ammonia cured epoxy resin, lead containing PVC wire, etc.

Solution:

Choosing our company's excellent anti poisoning products can solve some poisoning problems.

If the poisoning is caused by excessive residual rosin on the surface of the road board, it should be cleaned with board washing water before gluing the product.

If poisoning is caused by silicone sealant or ammonia cured epoxy resin, please contact our company to recommend excellent dealcoholized titanium or additive sealant or non ammonia epoxy resin.

If PVC wire causes poisoning, silicone wire can be replaced for use. If rubber gloves cause poisoning, silicone rubber gloves can be used.

Shanghai Hinnel provides innovative adhesive solutions for bonding, sealing, potting, thermal conductivity, and protection. Our staff work closely with customers to help them increase the value of their products. In the ever-changing market, we constantly innovate, respond quickly, and are committed to providing professional products and technical support to global customers.

Data Download