Will electronic potting glue cause corrosion to electronic components?

Electronic potting glue, as a key protective material, has been widely used in the electronics industry. It not only ensures the stability and reliability of electronic components but also supports the development of various high-end technologies. Shanghai Hinnel New Materials Technology Co., Ltd. introduces: Does electronic potting glue cause corrosion to electronic components?

Shanghai Hinnel

2025/02/11

Electronic potting glue does not corrode electrical components, as it can form a sealed state after potting, protecting the electrical components and preventing external moisture and water intrusion. Moreover, it presents an elastic volume after curing, which can protect the electrical components from delamination and detachment during vibrations.

However, improper use during the process, such as misuse or exceeding its applicable range, may lead to a decline in the performance of electronic potting glue or adversely affect electronic components. Therefore, when using electronic potting glue, it is necessary to follow the correct usage methods and precautions to ensure the performance and stability of the product.

The main uses of electronic potting glue include the following aspects:

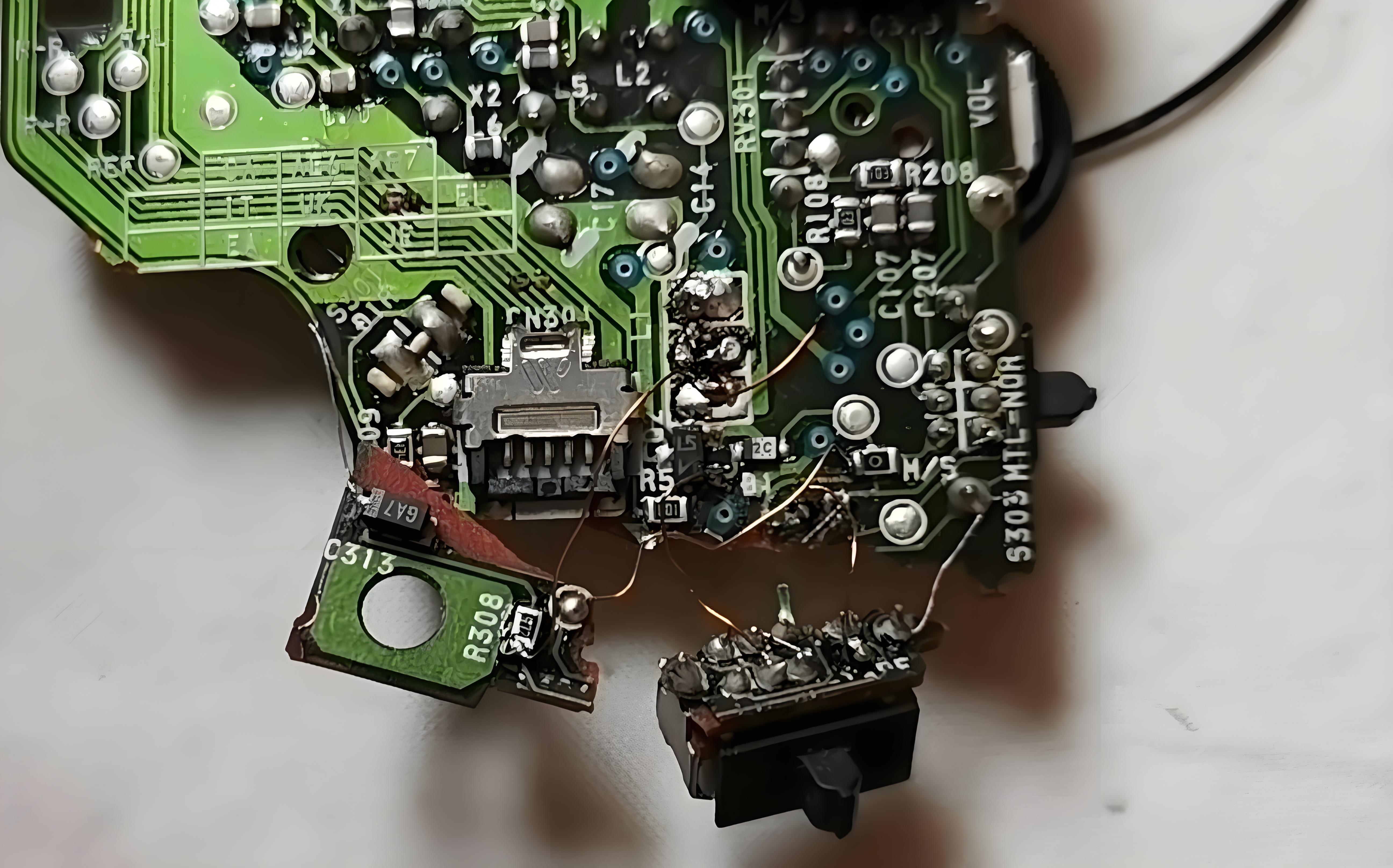

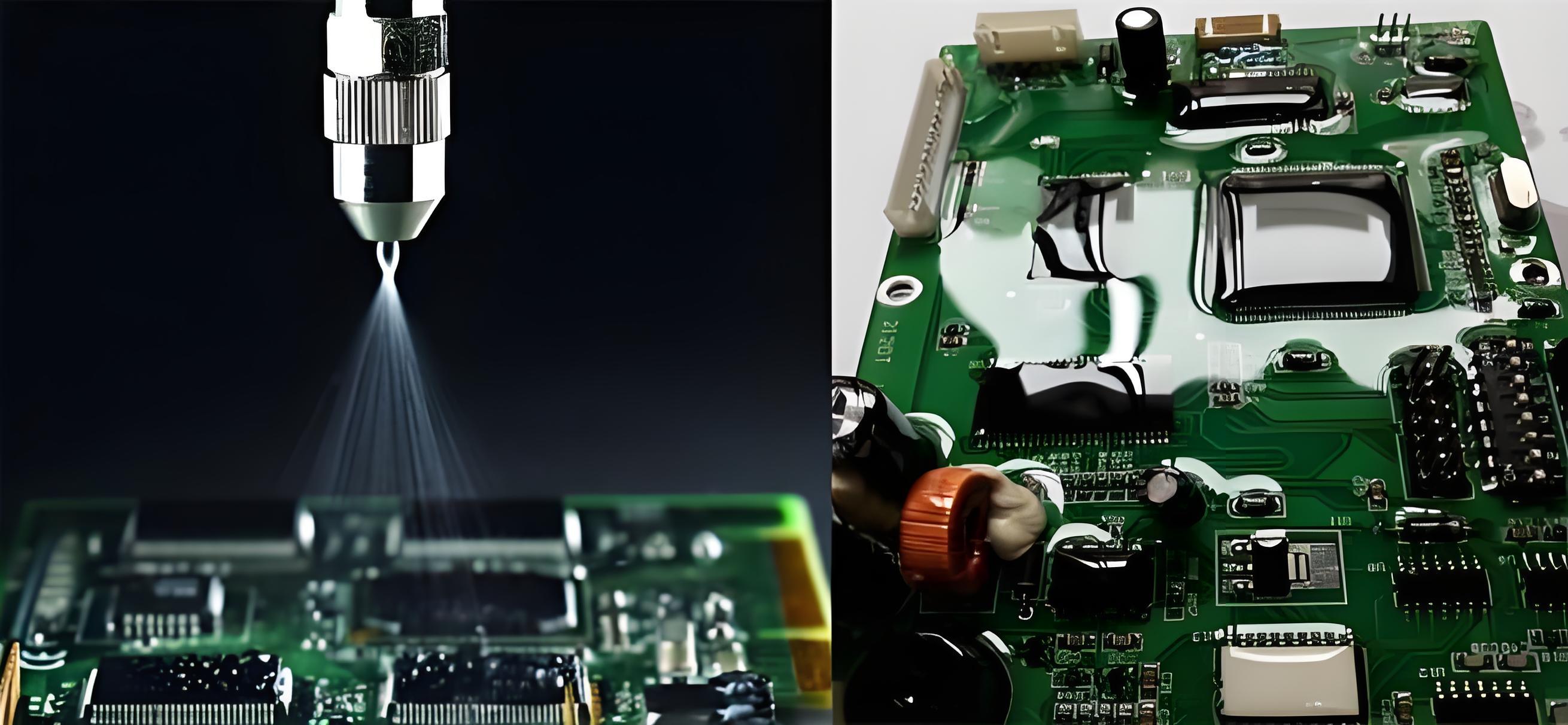

1.Potting: Electronic potting glue can fix electronic components onto the substrate and fill the gaps between the substrates, forming a sealed circuit board. This potting can protect the circuit board from environmental influences such as temperature, humidity, dust, and vibration, while also improving the insulation performance and mechanical strength of the circuit board.

2.Adhesion: Electronic potting glue can be used to bond various electronic components, such as capacitors, resistors, inductors, transistors, and integrated circuits. It can form stable connections and enhance the mechanical strength and stability of the components.

3.Protection: Electronic potting glue can protect electronic components from mechanical damage and chemical corrosion. In some cases, potting glue can also prevent electromagnetic interference, ensuring the normal operation of the circuit.

4.Heat dissipation: Some electronic potting glues have excellent thermal conductivity, which can dissipate the heat generated by electronic components, lowering the temperature of the components and thus extending the lifespan of electronic products.

5.Sealing: Electronic potting glue can seal the outer casing of electronic products, preventing moisture and dust from entering the product, ensuring the stability and reliability of the product.

Applications of electronic potting glue in the electronics industry:

1.Sensor packaging: Electronic potting glue is widely used in the packaging of sensors, protecting sensor components and circuits from damage and ensuring their normal operation. Recommended use:9001AB-3TQ、9001AB Epoxy potting glue, transparent flexible epoxy potting glue, quick curing, yellowing resistant, good adhesion to plastic housings, not easy to peel off, good waterproof performance, low shrinkage, and good adhesion.

2.Epoxy potting glue, transparent flexible epoxy potting glue, quick curing, yellowing resistant, good adhesion to plastic housings, not easy to peel off, good waterproof performance, low shrinkage, and good adhesion.Packaging: Inthe packaging of lamps, electronic potting glue can protectPackaging: Inchips, circuit boards, and solder joints, improvingPackaging: Inthe durability and stability of the lamps. Recommended use:Packaging: InSilicone sealant, high transparency, titanium ester type adhesive sealant, good adhesion, low volatility, low odor, good elasticity and high strength after curing, used for sealing waterproof and bonding.HN733WSemiconductor packaging: With the development of microelectronics technology, the size of integrated circuits is getting smaller, while performance requirements are increasing. Electronic potting glue plays a key role in this field, providing physical and chemical protection for microchips, ensuring their stable operation under various environmental conditions.

3.Semiconductor packaging: with the microelectronics technology, the size of integrated circuits is getting smaller and smaller, while the performance requirements are getting higher and higher. Electronic potting compound plays a key role in this field, provides physical and chemical protection for microchips, to ensure its stable work in a variety of conditions. Recommended use: HN8730 silicone potting compound, thermally conductive flame retardant anti-poisoning silicone potting compound, good permeability, long operation time, fast curing speed.

4.PCB (Printed Circuit Board) Protection: PCB is the core part of modern electronic equipment. Electronic potting compound provides a uniform protective film for PCB, preventing external factors from causing damage to it and ensuring the stable operation of the circuit. Recommended use: PU550AB/PU550-2 polyurethane potting compound, excellent self-exhaustion foam performance, excellent resistance to double 85 performance (can withstand more than 1000 hours), excellent resistance to cold and hot shock performance (-45 ~ 125 ℃), the adhesion of metals, plastics, wiring harnesses and so on.

In conclusion, electronic potting compound, as an important electronic sealing material, plays an important role in the modern electronic industry. It can not only protect electronic components from influence and mechanical damage, but also improve the insulation performance and mechanical strength of the circuit board. With the continuous and growing demand of the electronics industry, the market prospect of electronic potting compound will be more broad.

Note: Part of the content from the network, if infringement contact deleted.

> Recommend reading

Shanghai Hinnel

2025/04/24

Product applications and performance characteristics of polyurethane structural adhesive

Shanghai Hinnel

2025/04/17

What are the common problems and solutions for silicone thermal potting glue?

Shanghai Hinnel

2025/04/15