What are the common problems and solutions for silicone thermal potting glue?

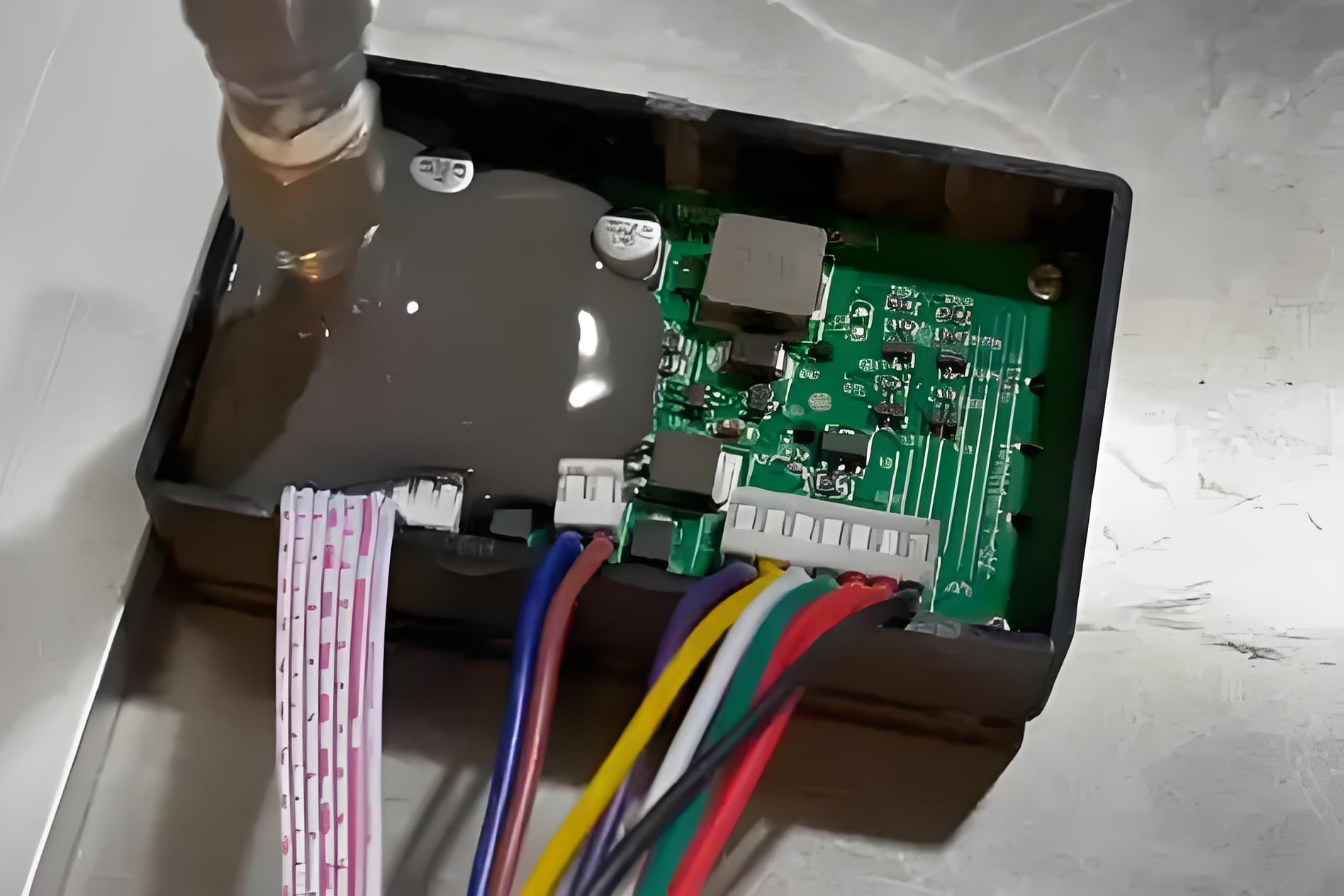

With the continuous development of technology, organosilicon potting compounds have been widely used in the packaging of electronic devices and other fields. However, in practical applications, users often encounter the following problems: incomplete curing or difficult curing, bubble formation during operation, cracking after curing, etc. These problems not only affect product quality but may also lead to equipment damage and project delays. Shanghai Hinnel New Materials Technology Co., Ltd. introduces you.

Shanghai Hinnel

2025/04/15

Incomplete or difficult curing

Human factors or errors in measuring tools may lead to incorrect adhesive ratios. Alternatively, insufficient curing time or temperature may result in incomplete curing, affecting the curing effect. 。

Solutions:

Regularly calibrate measuring tools to ensure accurate adhesive ratios. Control curing temperature and time If necessary, increase the curing temperature or extend the curing time. 。

Bubble formation during operation

Silicone potting compounds are usually A 、 B Two components mixed together. If the mixing is not uniform, and the two components do not react completely, gas is easily generated during the curing process, resulting in bubbles. Curing temperature, humidity, and curing time all affect the curing effect of the potting compound.

Solutions:

During stirring, ensure uniform mixing to avoid air entrainment, and perform vacuum treatment if necessary. When heating the silicone potting compound, avoid excessively high or low temperatures to ensure that the material is operated at a suitable temperature. 。

Cracking after curing

External environmental factors such as temperature changes, humidity, and mechanical vibrations can also affect the performance of the potting compound. In harsh environments, the potting compound is more prone to cracking. During construction, inaccurate mixing ratios, uneven mixing, improper potting operations, etc., may affect the performance of the potting compound, leading to problems after curing.

Solutions:

In application scenarios, minimize the impact of external environments on the potting compound, such as enhancing heat insulation and maintaining constant temperature and humidity. Strictly follow the manufacturer's construction guidelines to ensure accurate mixing ratios, uniform mixing, and proper potting operations.

Choosing high-quality silicone potting compound and using the correct method will reduce some trouble and make it easy to use. For example: Hinnel's HNSIL8730 Silicone potting compound With excellent high and low-temperature resistance, it can maintain elasticity and softness at -50~250℃ It has good adhesion to heating components, high thermal conductivity, is repairable, and produces no bubbles during curing. We recommend that you Enter the Hinnel website to learn more about our products.

> Recommend reading

Shanghai Hinnel

2025/04/24

Product applications and performance characteristics of polyurethane structural adhesive

Shanghai Hinnel

2025/04/17

What are the common problems and solutions for silicone thermal potting glue?

Shanghai Hinnel

2025/04/15