Adhesive solutions for power supplies - polyurethane potting adhesives

The power supply is a crucial component in electronic devices, and its performance directly affects the efficiency and stability of the entire system. Polyurethane potting compound, as a high-performance insulating material, is widely used in the protection and sealing of power supplies. However, traditional potting compound solutions have many shortcomings, such as poor high-temperature resistance and aging resistance, which seriously restrict the performance of power supplies. Next, Shanghai Hinnel New Materials Technology Co., Ltd. will introduce the power supply potting solution.

Shanghai Hinnel

2025/04/08

To address these challenges, this newly launched innovative solution employs advanced polyurethane technology and a unique formulation design, aiming to enhance the reliability and durability of the drive power supply. According to experimental tests, this solution boasts the following significant advantages:

Protective Performance: It offers moisture-proof, waterproof, dust-proof, and corrosion-resistant properties, preventing moisture and dust from entering and causing short circuits or component failure. ; It is high-temperature and aging-resistant, 85 ,ensuring long-term stability in humid and hot environments.

Mechanical Performance: It possesses load-bearing capacity, supporting internal components to prevent damage from vibration or collisions. 。

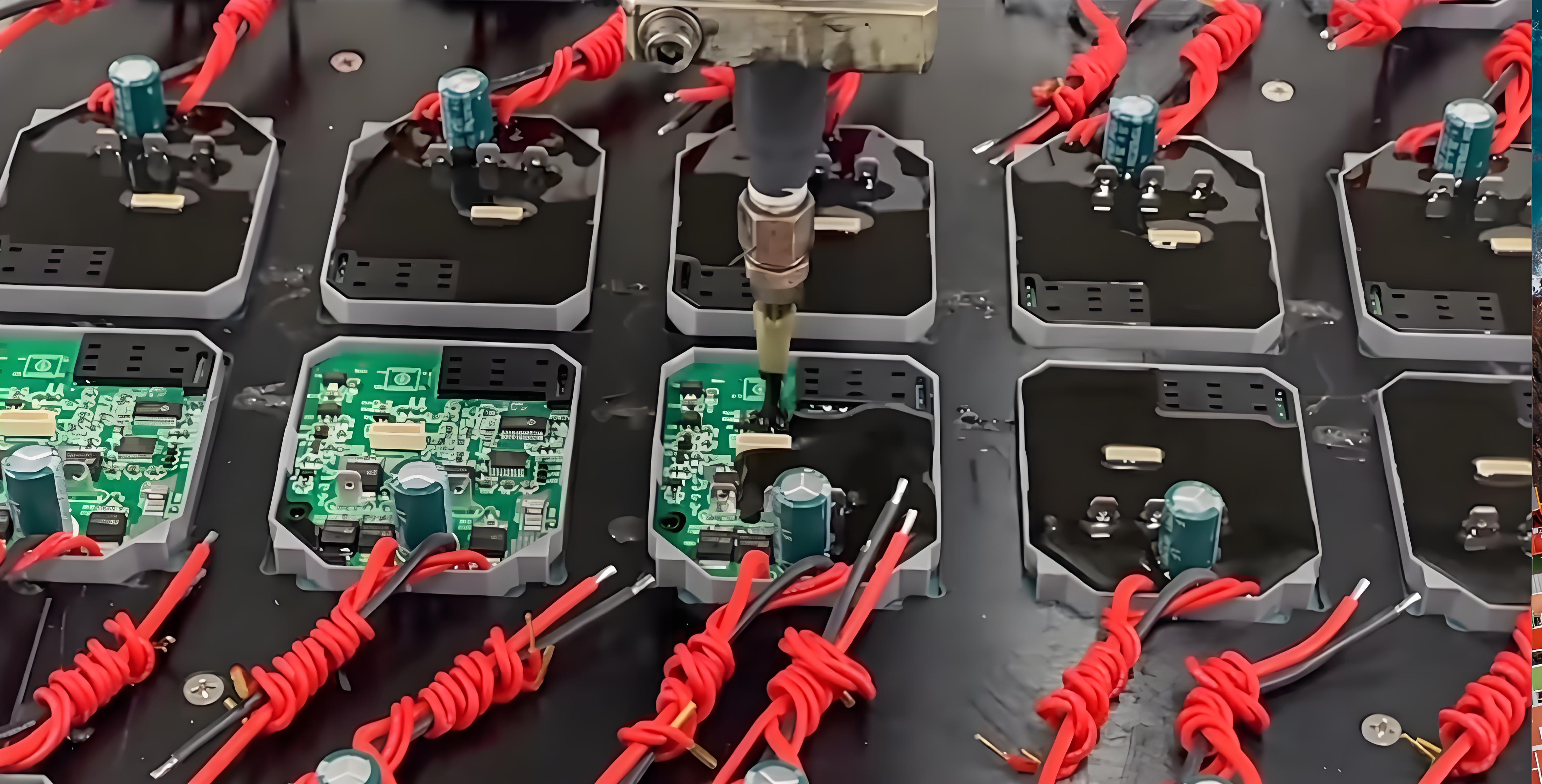

Encapsulation Process: It uses a unique encapsulation process to ensure that the potting compound uniformly covers the surface of the power supply components, forming a good sealing layer. This not only improves the waterproof performance of the power supply but also effectively prevents dust and impurities from entering the power supply, extending its service life.

Thermal Conductivity and Insulation: Thermal conductivity ≥ 0.5 W/(m·K) ,optimizing heat dissipation performance and reducing the risk of thermal failure in high-power density devices 。After curing, it maintains stable electrical insulation performance and isolates electromagnetic interference. 。

High Viscosity, Thixotropic: Hinnel polyurethane potting adhesive has high viscosity and thixotropic properties, effectively filling the gaps and crevices inside the power supply module during the potting process to ensure a good potting effect.

Anti-Toxicity: The polyurethane sealant has anti-toxicity properties and will not corrode or damage the internal components of the power supply, ensuring the long-term stable operation of the power supply.

Hinnel Drive Power Supply Potting Adhesive Usage :

Mixing: Before mixing, check A component for filler sedimentation. If sedimentation occurs, stir it evenly first (this step is not needed for transparent systems). Then, use manual or automatic equipment to mix the A/B components proportionally by ( weight ratio ) and mix evenly. For applications sensitive to air inclusion, the mixed adhesive should be degassed under a vacuum of -0.09MPa or higher for 3~5 minutes. For larger quantities of adhesive, extend the degassing time accordingly. The purpose is to remove air bubbles mixed into the adhesive during stirring; otherwise, there is a certain probability that air bubbles will appear inside and on the surface of the cured adhesive. For mass production, automatic metering and / mixing / equipment can be used.

Pouring: Manual or automatic potting equipment with a vacuum device, a stirring device, and a material tank insulation device can be used (a stirring device is not needed for transparent systems). Place the component to be potted horizontally with the pouring port upwards and pour in the potting compound within the operable time for self-leveling. For complex and large components, , pouring should be done in multiple steps. Air bubbles can be removed by blowing with a hot air gun to eliminate surface bubbles.

Curing: It is recommended to allow the adhesive to cure in a static state at 20℃~30℃ for better bubble elimination, or low-temperature heating curing when there are no obvious air bubbles inside and on the surface of the adhesive. The curing time depends on the amount mixed each time and the temperature. For larger quantities or higher temperatures, the curing time will be shorter. Conversely, the curing time will be longer. Catalysts greatly shorten the curing time.

Cleaning: The uncured resin is easy to clean. For cured resin, please use a special cleaning agent to soak (e.g., thinner, dichloromethane, plate washing solution, etc., but it does not rule out the possibility that the cleaning agent will corrode other components besides the adhesive. Please use with caution.), soften, and peel off. ( In summary, using polyurethane potting adhesive for encapsulating drive power supplies offers many advantages, enhancing performance, stability, safety, and service life. Therefore, the appropriate polyurethane potting adhesive should be selected based on specific circumstances during production and use. If you have any questions or needs, please feel free to contact us. We will wholeheartedly serve you and provide you with an appropriate protective solution for your drive power supply.

Note: Some images are from the internet. Please contact us for removal if there is any infringement.

注:部分图片来源与网络,如有侵权联系删除。

Previous Page:

> Recommend reading

Shanghai Hinnel

2025/04/24

Product applications and performance characteristics of polyurethane structural adhesive

Shanghai Hinnel

2025/04/17

What are the common problems and solutions for silicone thermal potting glue?

Shanghai Hinnel

2025/04/15