Common problems and solutions for polyurethane potting glue

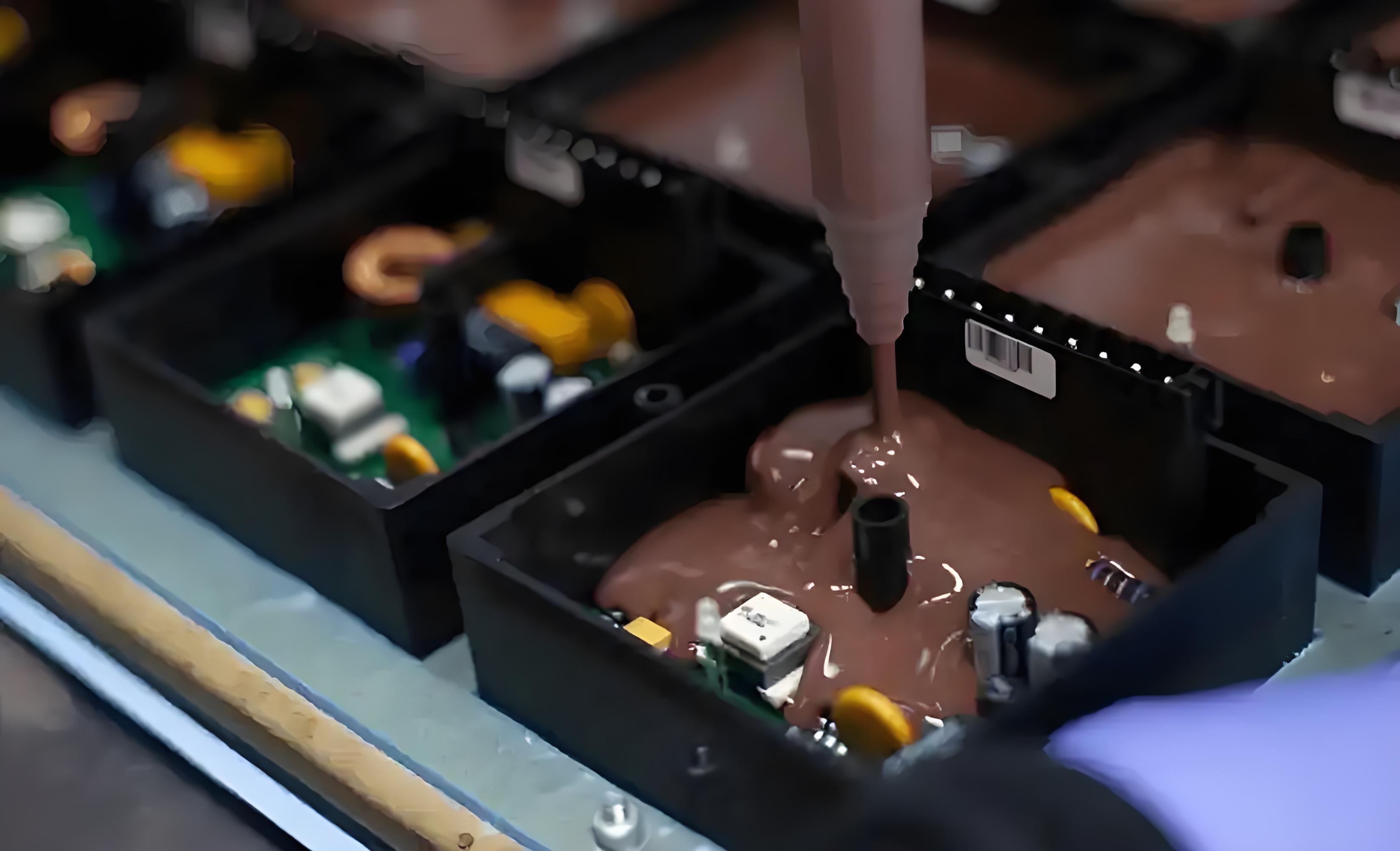

With the continuous development of technology, the importance of polyurethane potting glue is becoming increasingly prominent, and its application scenarios are constantly expanding. Its main functions are to protect electronic components, improve insulation performance, enhance waterproof performance, and improve overall structural strength. However, during use, many users may encounter some problems and challenges. Next, Shanghai Hinnel New Materials Technology Co., Ltd. will introduce common problems and solutions for polyurethane potting glue.

Shanghai Hinnel

2025/04/01

Excessive curing time

In some cases, the curing time of polyurethane potting glue may exceed expectations. This may be related to ambient temperature, humidity, glue quality, and mixing ratio.

Solution:

To address the issue of excessive curing time, users can adjust the temperature and humidity of the construction environment to accelerate the curing speed. At the same time, ensure the use of high-quality polyurethane potting glue purchased through legitimate channels, and strictly follow the product Description for mixing and use.

Bubbles after curing

The selected product has poor defoaming properties. Air is entrapped during the mixing process, and vacuum degassing is not performed; before use, the product is not mixed evenly, resulting in an excessive amount of polyol after mixing, which will also produce bubbles.

Solution:

To address the problem of bubbles after curing, users can choose products with good defoaming performance and vacuum them after mixing the base and curing agent. Preheating the product to be potted will help air to escape. Cure in a room with lower temperature and humidity to allow sufficient time for the air to escape.

Poor adhesion to substrate

If the polyurethane potting glue does not reach the expected strength or bonding effect after curing, it may be due to improper surface treatment of the substrate or incorrect mixing ratio.

Solution:

To address poor adhesion, first ensure that the substrate surface is properly treated, such as sanding and cleaning. Second, strictly follow the mixing ratio in the product Description to ensure that the glue performance is fully utilized.

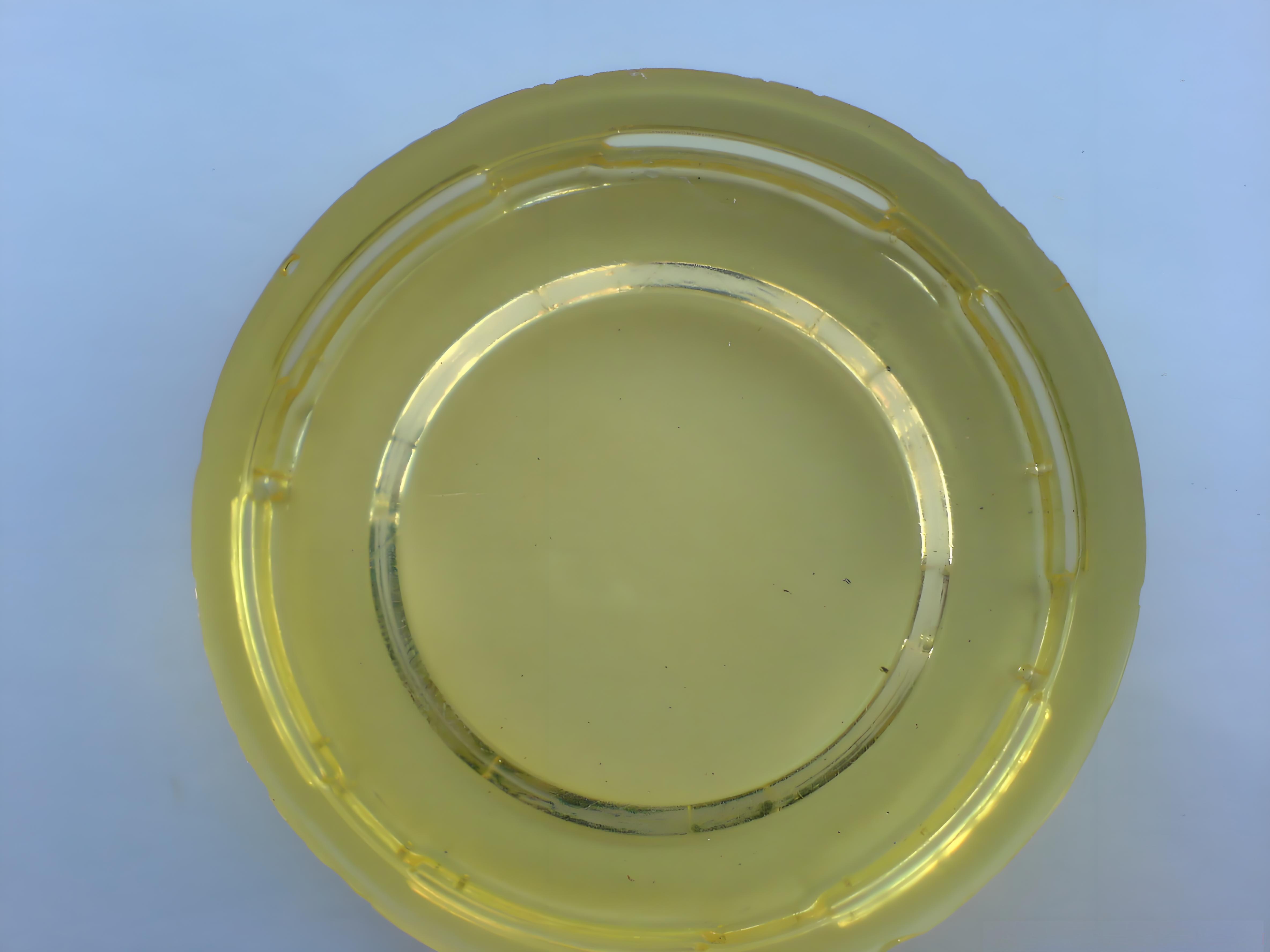

Color change or yellowing

Polyurethane materials are affected by ultraviolet rays, light, ambient temperature, air humidity, and other environmental factors during the curing process, resulting in yellowing after curing. In addition, long-term use and improper maintenance will also accelerate the aging and yellowing of polyurethane materials.

Solution:

To address the problem of color change or yellowing after polyurethane curing, choose a UVUVresistant polyurethane adhesive to reduce the impact of light on color. Avoid exposure to direct sunlight or high temperatures during storage and use. Choose cool and dry storage conditions, and the polyurethane products should be cleaned, wiped and maintained regularly.

Uneven surface after solidification

Excessive humidity or low temperature in the construction environment can lead to incomplete solidification of polyurethane, resulting in an uneven surface. Inadequate construction techniques or improper operation can also lead to incomplete solidification of polyurethane, or the use of poor quality materials, which can also easily lead to an uneven surface.

Solution:

Maintaining a suitable humidity and temperature in the construction environment can effectively prevent incomplete polyurethane solidification. Paying attention to technical details during construction, operating according to requirements, and choosing high-quality materials can effectively prevent uneven surfaces.

If the uneven surface of the solidified polyurethane is severe and cannot be resolved by sanding, it is recommended to consider re-construction.

Polyurethane potting glue, as a high-quality sealing material, can bring great convenience to users under the premise of correct use. For problems that may be encountered during use, as long as we adopt the correct solution strategies, we can ensure that the product performance is fully utilized. Hinnel has a wide range of innovative polyurethane potting glue product series with a variety of mechanical properties, including gel properties, elastomer properties, impact resistance, large size stability, and transparent options for transparent applications.UVSolutions. We can quickly respond to glue needs. Welcome users to consult and understand.

Note: Some content comes from the Internet. Please contact us to delete if there is any infringement.

> Recommend reading

Shanghai Hinnel

2025/04/24

Product applications and performance characteristics of polyurethane structural adhesive

Shanghai Hinnel

2025/04/17

What are the common problems and solutions for silicone thermal potting glue?

Shanghai Hinnel

2025/04/15