Are there differences in epoxy structural adhesives used in different application scenarios?

With the continuous development of technology, epoxy structural adhesives, as high-performance bonding materials, are widely used in various scenarios. Shanghai Hinnel New Materials Technology Co., Ltd. introduces their differences in different application scenarios.

Shanghai Hinnel

2025/03/20

Epoxy structural adhesive Application scenarios are as follows:

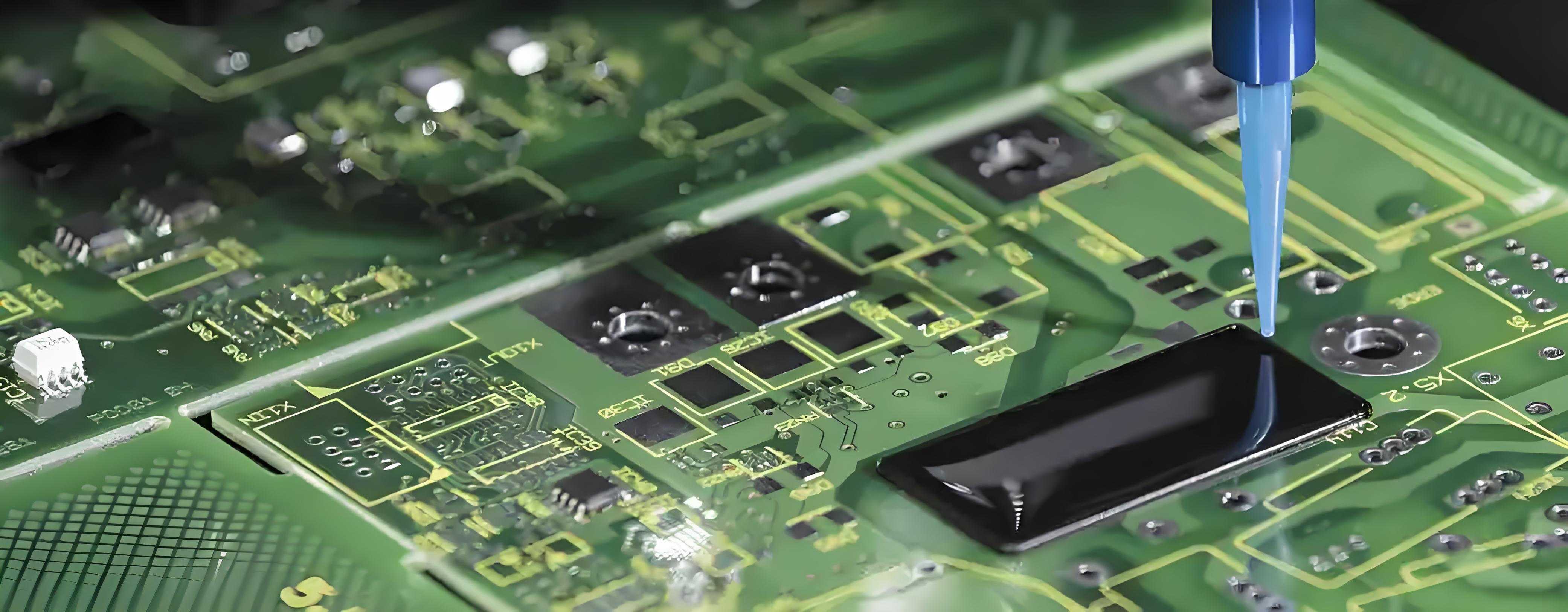

Electronics and electrical applications In the electronics and electrical fields, epoxy structural adhesives are not only used for bonding mechanical structures, but also widely used to prevent electrical short circuits and other problems due to their good electrical insulation properties. Their high insulation performance ensures the stable operation of electronic equipment. 。

Coating industry In the coatings industry, epoxy structural adhesives are mainly used to prepare water-based coatings, powder coatings, and high-solids coatings. Their excellent bonding strength, chemical corrosion resistance, and low shrinkage rate make them widely used in pipelines, containers, automobiles, ships, aerospace, and other fields. 。

Craft applications Crafts often need to showcase exquisite and unique designs. The application of epoxy structural adhesives in the craft field is mainly to increase the firmness and aesthetics of the product. Epoxy structural adhesives in this field may have a wider variety of choices in terms of color and transparency.

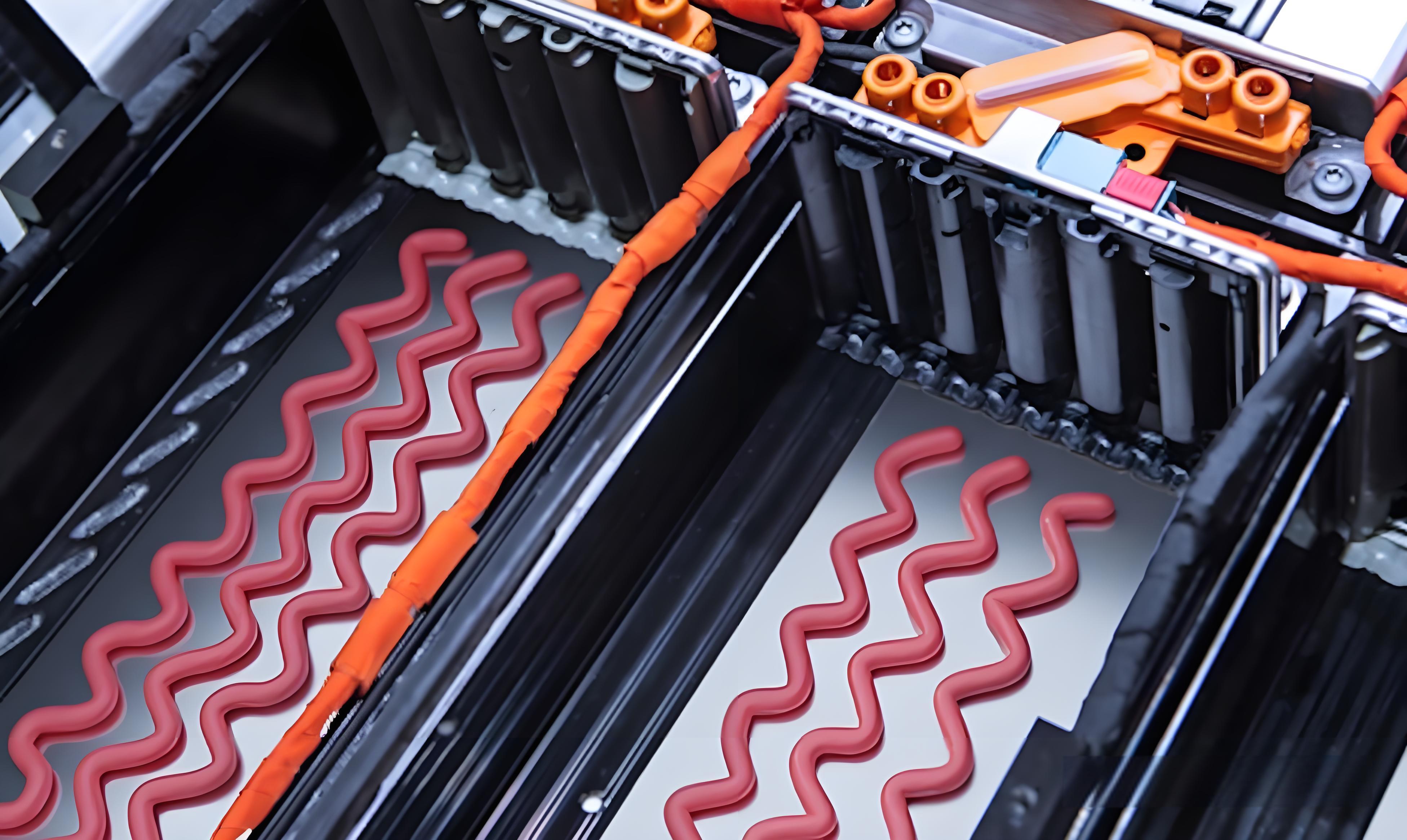

Motor applications In motor manufacturing, epoxy structural adhesives are mainly used to bond motor components, ensuring stability under high loads and frequent start-up conditions. Epoxy structural adhesives have high strength, high temperature resistance (they can remain stable in a wide temperature range of -40°C to 200°C ), chemical corrosion resistance, and good electrical insulation properties, making it particularly important in motor manufacturing. 。

Construction applications In the construction industry, epoxy structural adhesives are mainly used for bonding materials such as stone, ceramics, and glass. Due to the variable construction environment, the adhesive is required to have good weather resistance and anti-aging properties. In addition, construction epoxy structural adhesives also need to consider environmental protection performance, such as low VOC etc.

Types of Hinnel Epoxy Structural Adhesives

1. Two-component epoxy structural adhesive

Two-component epoxy adhesives are made by mixing two components. They are highly transparent, cure quickly, and can cure at room temperature, suitable for bonding larger areas or applications requiring longer working times. They have extremely high bonding strength, and the cured structure is very strong. Two-component epoxy adhesives are widely used in bonding motor housings, brackets, and other components.

2. One-component epoxy structural adhesive

Thixotropic paste-like, non-sagging, long-curing, one-component epoxy resin structural adhesive. Easy to use, it can be quickly cured by heating. Very long shelf life, at room temperature 20~25℃ can be stored for 90 days, 0~5℃ can be stored for 180 days, used for structural bonding or caulking, has strong toughness after curing, excellent bonding strength and high temperature resistance.

In summary, Epoxy structural adhesive is a material with broad application prospects. Different structural adhesives have different application fields and characteristics due to their unique chemical properties and manufacturing processes. Therefore, when choosing a structural adhesive, it should be selected according to actual needs and application scenarios.

Note: Some content comes from the Internet. Please contact us to delete it if there is any infringement.

> Recommend reading

Microwave oven bottom plate bonding solution: High-strength bonding performance of silicone sealant

Shanghai Hinnel

2025/06/10

Epoxy structural adhesive: professional bonding, high-performance, wide application

Shanghai Hinnel

2025/06/04

Sealing and protection applications of silicone gel in electronic components

Shanghai Hinnel

2025/05/29