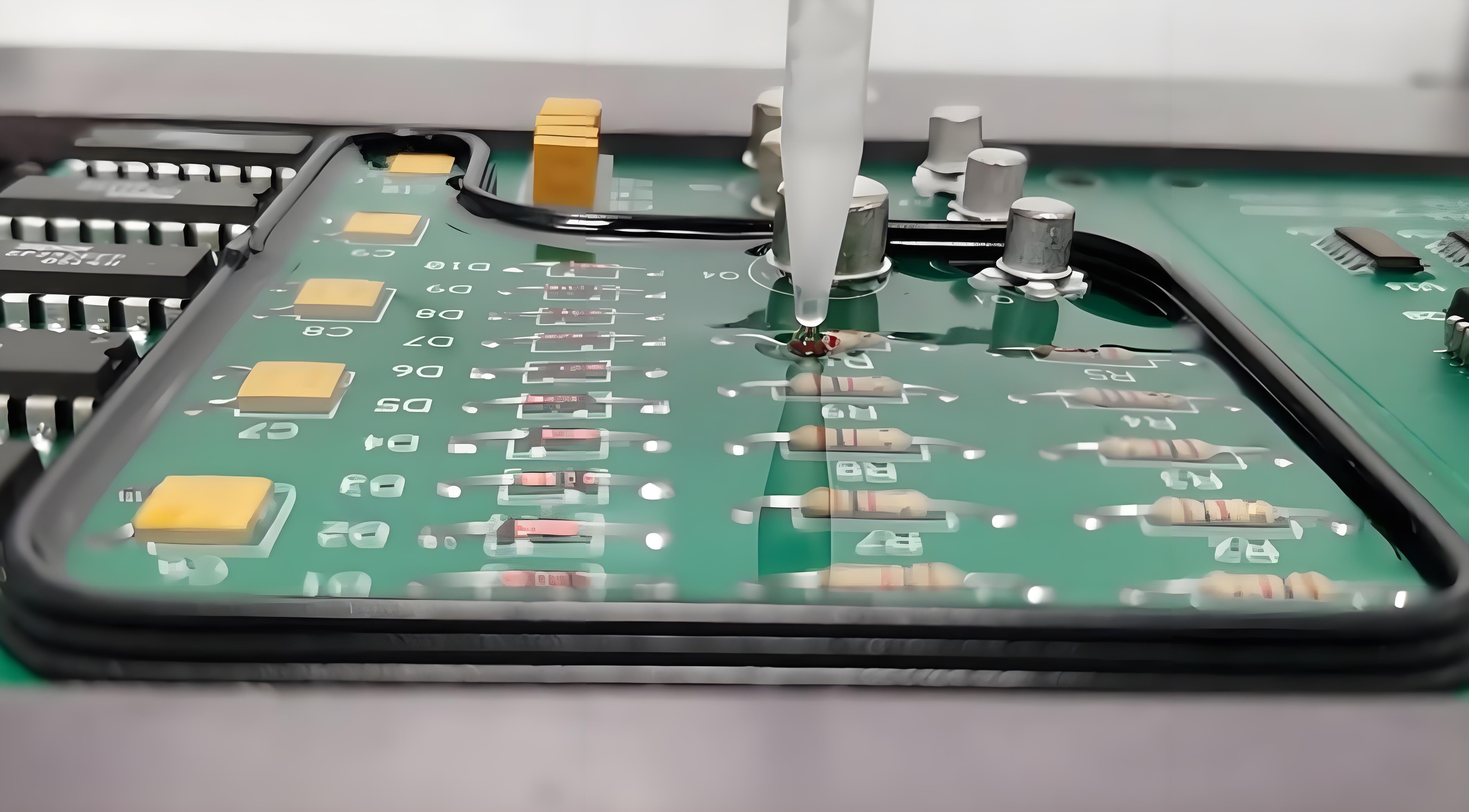

Sealing and protection applications of silicone gel in electronic components

With the rapid development of technology, the market demand for organosilicon gel is constantly growing. Silicone gel has good electrical conductivity and plasticity, and can be used as an important material for manufacturing electronic components. So, what are the advantages and application industries of organosilicon gel? Shanghai Hinnel New Materials Technology Co., Ltd. will introduce it to you.

Shanghai Hinnel

2025/05/29

What is silicone gel?

Silicone gel is a high-performance polymer material with excellent electrical insulation, temperature resistance, waterproof and moisture-proof properties, chemical corrosion resistance, and stability. It is widely used in electronic components and plays a crucial role in improving the performance and reliability of components.

Application industries of silicone gel

Due to its high temperature resistance, softness, and shock absorption, silicone gel is mainly used in the following areas:

Electronic packaging: Silicone gel can be used to protect sensitive components and prevent external environmental influences.

Photovoltaic components: Silicone gel is often used to encapsulate photovoltaic junction boxes, providing good sealing and waterproof performance.

Medical devices: Due to its biocompatibility, silicone gel is also used to make artificial organs and medical materials.

Hinnel Silicone Gel Product Introduction

Hinnel Silicone Gel It has excellent fluidity, very good self-defoaming performance and processability. It can be used in -65 ~ 200℃ temperature range for long-term use. It has excellent electrical and chemical stability, physiological inertness, low oil permeability, low volatility, and anti-toxicity. After curing, no pretreatment agent is needed. It can maintain long-lasting pressure-sensitive adhesion to most materials, excellent self-repair function, and self-healing function in case of minor damage, which can provide better sealing performance.

Why choose Hinnel silicone gel?

Hinnel silicone gel undergoes rigorous quality testing and production process control to ensure that the quality and performance of the products meet high standards. We use advanced production processes and raw materials to ensure the quality and performance of our products are stable and reliable. At the same time, we also provide perfect after-sales service to provide customers with effective support and assistance. Welcome to contact Hinnel New Materials for free samples and technical support through website messages, calls, and emails!

Related articles: Recommended potting glue for rain gauge sensors: Hinnel HNGel5270 silicone gel

> Recommend reading

Epoxy structural adhesive: professional bonding, high-performance, wide application

Shanghai Hinnel

2025/06/04

Sealing and protection applications of silicone gel in electronic components

Shanghai Hinnel

2025/05/29

Shanghai Hinnel

2025/05/27