Applications and common issues of silicone sealant

With the continuous advancement of technology and the increasing awareness of environmental protection, silicone sealants will be applied in more fields. Especially in new energy and environmentally friendly materials, the excellent performance of silicone sealants will be further utilized. Shanghai Hinnel New Materials Technology Co., Ltd. introduces the uses and common problems of silicone sealants.

Shanghai Hinnel

2025/08/07

What is Silicone Sealant ?

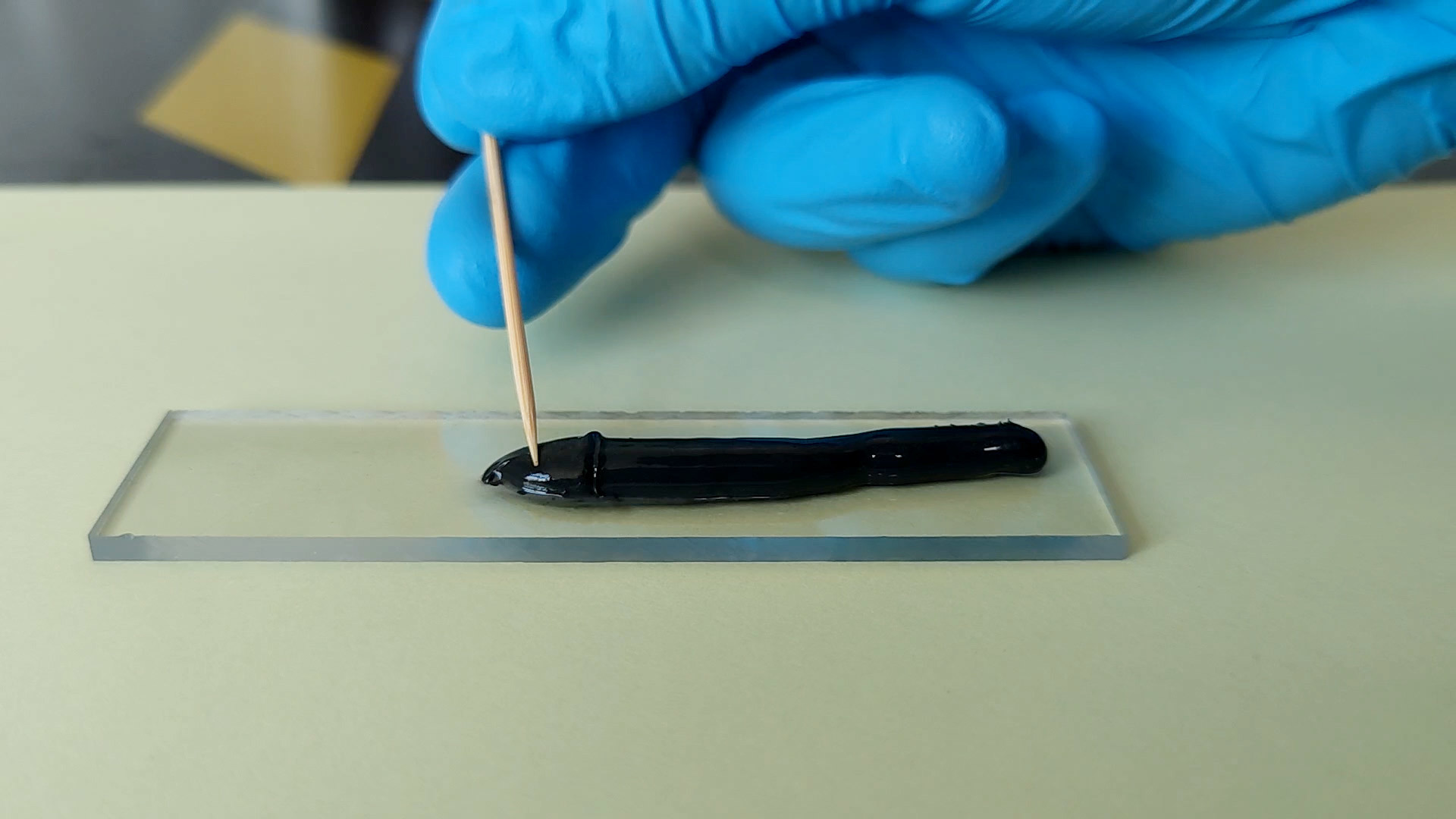

Silicone sealant is a high-performance sealing material mainly composed of organosilicon compounds. The temperature range is -55℃~315℃ approximately. It stands out among numerous sealing materials due to its unique physical and chemical properties, such as excellent weather resistance, high-temperature resistance, corrosion resistance, and anti-aging properties.

Main functions of silicone sealant

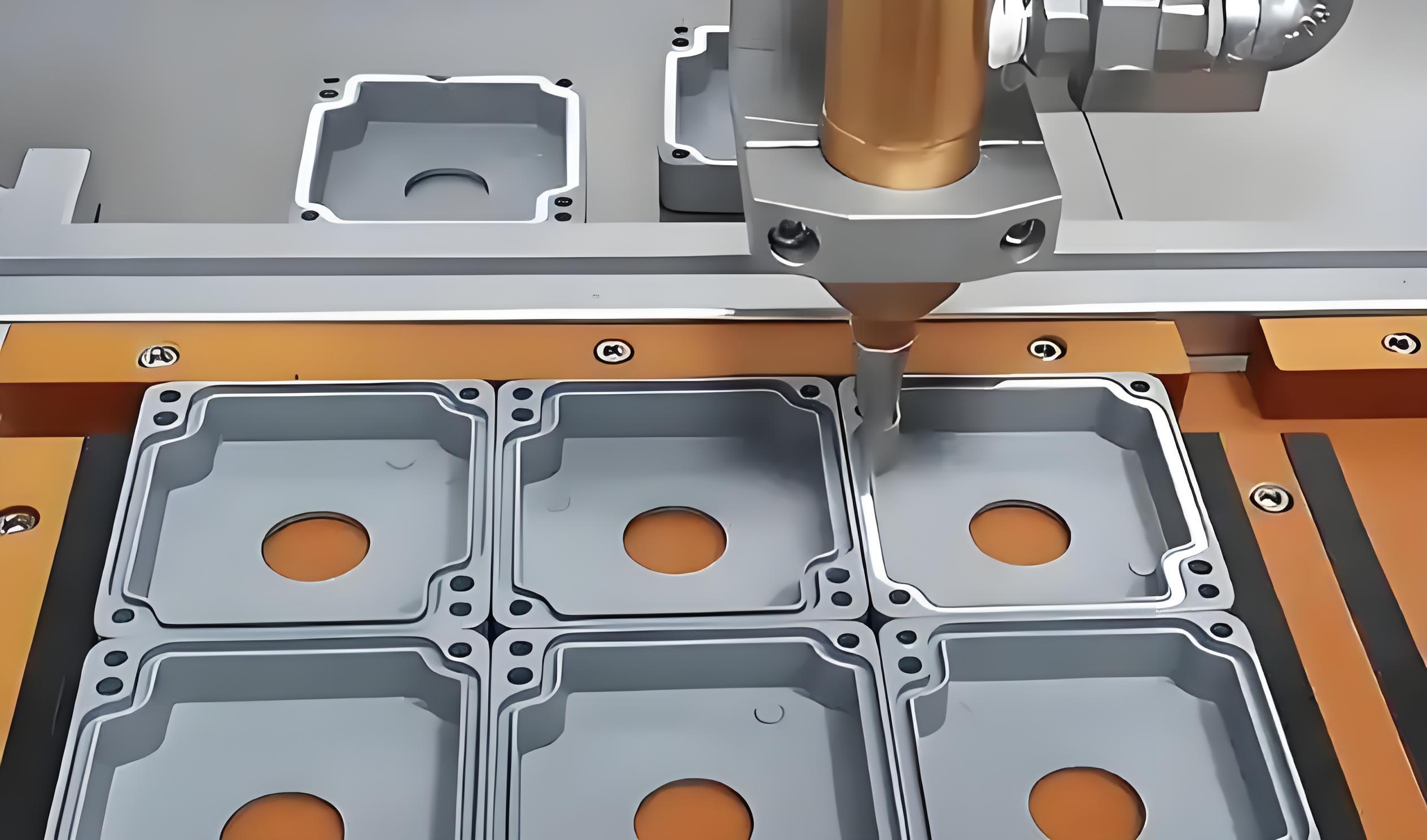

1. Filling and sealing: Due to its excellent elasticity and water resistance, silicone sealant is often used to fill gaps between building materials, effectively preventing the intrusion of water, gas, and other external environments, and ensuring the sealing performance of buildings.

2. Bonding and fixing: In building curtain wall projects, silicone sealant can bond various materials together to form a stable structure, ensuring its integrity and stability.

3. Seismic buffering: Due to the good elasticity of silicone sealant, it can absorb and disperse the vibration energy generated by earthquakes or other external forces, protecting buildings from damage.

4. Strong weather resistance: Silicone sealant can resist the impact of climate change. It maintains good performance in both hot summers and cold winters, effectively preventing interface gap problems caused by temperature changes.

Silicone Sealant Common problems:

(1) Why is there a viscosity difference in silicone bonding sealant in winter and summer? ?

The viscosity of the glue will change with temperature. The viscosity will decrease at high temperatures in summer, and vice versa in winter, but it will be within the acceptable range.

(2) How to improve the curing speed of silicone sealant? ?

Silicone sealant relies on moisture to initiate the vulcanization reaction. Increased humidity can significantly accelerate the curing process; and increasing the ambient temperature, but avoid exceeding 40°C to prevent bubble formation; the recommended single coating thickness should not exceed 3 mm, excessive thickness will lead to slow internal curing; ensure uniform thin coating to improve overall efficiency.

(3) Solutions for uncured silicone sealant

Insufficient temperature leads to incomplete curing. A suitable temperature is needed for the silicone sealant to cure completely. If construction is carried out at low temperatures, suitable heating conditions should be provided to achieve curing at room temperature. Storage should avoid humid and high-temperature environments to avoid affecting its performance.

° Send email to Send email to sales@hinnel.com Email ;

° Call technical support +86-18301723907 Inquiry.

Note: Some images are from the Internet. Please contact us for removal if there is any infringement.

> Recommend reading

Common issues encountered during the use of polyurethane structural adhesives

Shanghai Hinnel

2025/09/18

What are the advantages of epoxy structural adhesive potting for motor rotors?

Shanghai Hinnel

2025/09/16