china Polyurethane potting adhesive

The Polyurethane Potting Adhesive is a high-performance solution designed to encapsulate and shield sensitive electronic components from moisture, chemicals, and mechanical stress. With excellent flexibility and adhesion, this adhesive is ideal for applications in automotive, renewable energy, and industrial electronics. Its low viscosity ensures thorough coverage,

2025/08/14

Excellent high and low temperature stability,

Designed for flexible, low-stress waterproof potting protection

The basic principle of polyurethane potting adhesive is the cross-linking curing of polyol resin and MDI curing agent under the action of a catalyst, forming a polymer. To achieve better bonding sealing, heat resistance, thermal conductivity, toughness, elasticity, and low stress functions, we need to make some improvements to ensure good thermal strength, mechanical properties, and insulation stability.

Hinnel has a wide range of innovative polyurethane potting adhesive products, which maintain good thermal stability even at continuous operating temperatures of up to 165°C, making the products suitable for demanding application requirements and expanding their application range. The fillability of the resin part significantly improves thermal conductivity, allowing designers to achieve excellent heat dissipation.

Hinnel's polyurethane potting adhesive has a variety of mechanical properties, including gel characteristics, elastomer characteristics, impact resistance, and large size stability. Transparent UV-resistant solutions can also be provided for transparent applications.

Product applications:

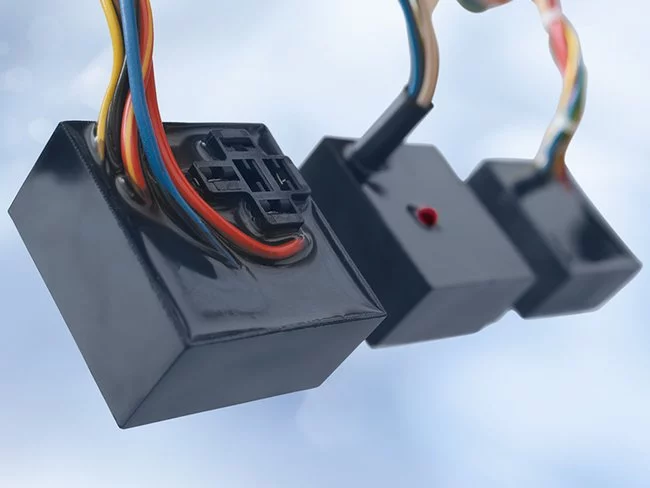

Potting protection for automotive electronic devices, sensors, electronic appliances, etc.; effective protection and insulation for electrical and electronic devices such as transformers, chokes, and capacitors, ensuring uniform heat dissipation; thermal waterproof potting for industrial power supplies and controllers; waterproof potting protection for new energy vehicle charging guns, and other industries.

The Polyurethane Potting Adhesive is a high-performance solution designed to encapsulate and shield sensitive electronic components from moisture, chemicals, and mechanical stress. With excellent flexibility and adhesion, this adhesive is ideal for applications in automotive, renewable energy, and industrial electronics. Its low viscosity ensures thorough coverage, even in complex molds, while its durable formulation resists cracking and delamination. Whether used for power modules, LED drivers, or PCB assemblies, the Polyurethane Potting Adhesive provides superior insulation and long-lasting protection.

One of the standout features of this Polyurethane Potting Adhesive is its exceptional resistance to thermal cycling and environmental extremes. It maintains elasticity across a wide temperature range, preventing stress fractures in fluctuating conditions. The adhesive cures at room temperature or with mild heat, speeding up production without compromising performance. Its excellent dielectric properties ensure electrical insulation, while its shock-absorbing qualities protect components from vibrations and impacts. Engineers rely on this Polyurethane Potting Adhesive for its ability to enhance device reliability in demanding applications.

| Model | Quality Ratio | Mixing Viscosity | Operation Time | Curing Time | Curing Hardness | Flame Retardant Level | Color | Main Characteristics |

| A:B | cps 25℃ | min 25℃ | hr 25℃ | Shore | UL-94 | - | ||

| PU500H | 100:50 | 650±200 | 20~30 | 24~72 | 75A | - | Colorless and Transparent | Colorless and pure transparent, used for LED light strips, smart water meters, and optical device potting, with excellent waterproof performance, fast curing speed, low exothermicity, high colloidal strength, and good toughness. |

| PU500D | 100:100 | 400±200 | 20~30 | 24~72 | 50D | - | Colorless and Transparent | Colorless and pure transparent, resistant to yellowing, high hardness, high toughness, adjustable curing speed, suitable for waterproof protection of electronic devices. |

| PU510F | 100:60 | 400±200 | 10~20 | 24~72 | 50D | - | Yellow Transparent | Acid and alkali resistant, hydrolysis resistant, low mixing viscosity, low exothermicity, strong adhesion to materials such as plastics and metals, suitable for water treatment filter membrane packaging. |

| PU550 | 100:20 | 500±200 | 50±10 | 12~24 | 80A | V-0 | Black | Very low viscosity, excellent self-degassing performance, can be manually or machine injected without bubbles, resistant to dual 85, with a bright and smooth surface. |

| PU550D | 100:20 | 800±500 | 30~40 | 24~72 | 80A | V-0 | Black | Very good resistance to dual 85, resistance to thermal shock, suitable for machine injection and heating curing, with good adhesion to metals, plastics, and wire harnesses, suitable for film capacitors, controllers, and automotive-grade sensor potting. |

| PU550-2 | 100:16 | 900±100 | 30±10 | 24~72 | 80A | V-0 | Black | Excellent resistance to dual 85 (can withstand over 1000 hours), excellent resistance to thermal shock (-45~125℃), with good adhesion to metals, plastics, and wire harnesses, suitable for automotive electronic sensor potting. |

| PU512 | 100:11 | 30000±10000 | 5±2 | 8~15min | 85A | V-0 | Black | Excellent resistance to dual 85, resistance to thermal shock, very fast curing speed, suitable for new energy vehicle charging gun potting. |

| PU515 | 100:33.3 | 500±200 | 30±10 | 24~72 | 50A | HB | Black | Resistant to low temperatures, excellent electrical insulation, good toughness, high elongation, with good adhesion to metals, quantities, and rubber. Resistant to dual 85 and thermal shock. |

| PU558 | 100:25 | 750±200 | 30~50 | 24~72 | 80D | V-0 | Black | Low viscosity, good fluidity, good gloss of the cured product, high hardness, high strength, high toughness, with good adhesion to metals and engineering plastics. |

Next page:

> Recommend reading

Epoxy potting compound enhances the structural reliability of buzzer assemblies.

Shanghai Hinnel

2025/12/04

Key Applications of Polyurethane Structural Adhesives in Power Battery Packaging Processes

Shanghai Hinnel

2025/12/03