China Thermal Conductive Materials

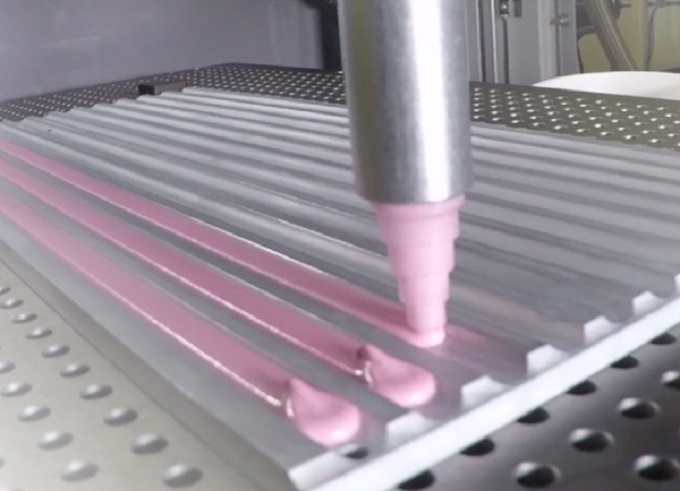

The transition to electric mobility and the demand for high-power industrial systems present unprecedented thermal management challenges. Pushing the boundaries of innovation, our next-generation thermal conductive materials are designed to handle the extreme heat fluxes and stringent reliability standards of these demanding applications.

2025/11/12

| Model | Quality Ratio | Mixing Viscosity | Operation Time | Curing Time | Curing Hardness | Thermal Conductivity | Dielectric Strength | Temperature Range | Flame Retardant Level |

| cps | min 25℃ | min | Shore 00 | W/m.k | KV/mm | ℃ | UL-94 | ||

| HN8730D | 1:1 | 200000~300000 | 60 | 24h@25℃/ 20min@80℃ | 50 | 2.0 | >10 | -50~200 | V-0 |

| HN8730D-1 | 1:1 | 200000~300000 | 5 | 30min@25℃/ 5min@80℃ | 50 | 2.0 | >10 | -50~200 | V-0 |

| HN8760D | 1:1 | 300000~400000 | 60 | 24h@25℃ /20min@80℃ | 60 | 3.5 | >10 | -50~200 | V-0 |

The transition to electric mobility and the demand for high-power industrial systems present unprecedented thermal management challenges. Pushing the boundaries of innovation, our next-generation thermal conductive materials are designed to handle the extreme heat fluxes and stringent reliability standards of these demanding applications. In the heart of an electric vehicle's battery pack or power inverter, efficient heat dissipation is not merely about performance—it is about safety and longevity. Our specialized thermal conductive materials provide the critical thermal linkage between cells, modules, and cooling plates, ensuring uniform temperature distribution and mitigating the risks of thermal runaway.

Our solutions for these high-stakes environments go beyond conventional offerings. We have developed a class of thermal conductive materials that combine superior heat transfer with essential properties like electrical insulation, flame retardancy, and long-term stability under thermal cycling. These include silicone-free thermal conductive materials for sensitive environments, fiber-reinforced composites for structural integrity, and soft, compliant gap pads that accommodate tolerance variations and stress in large assemblies. This engineered approach ensures that our materials perform consistently, even in the face of constant vibration, harsh chemicals, and extreme temperature fluctuations common in automotive and industrial settings.

Implementing our advanced thermal conductive materials translates directly into a competitive advantage. By enabling more efficient thermal management, you can design more compact systems, utilize higher power densities, and achieve faster charging capabilities—all while ensuring the utmost safety and meeting rigorous industry certifications. Our commitment is to provide not just a product, but a partnership in thermal innovation. Let us help you overcome your most complex thermal challenges and power the future with confidence and reliability.

> Recommend reading

Epoxy potting compound enhances the structural reliability of buzzer assemblies.

Shanghai Hinnel

2025/12/04

Key Applications of Polyurethane Structural Adhesives in Power Battery Packaging Processes

Shanghai Hinnel

2025/12/03